Adding Color to Injection Molding: A Comprehensive Guide

By:Admin

{Company Name} is a leading manufacturer and supplier of injection molding machinery and equipment, with a strong focus on advanced color injection molding solutions. The company's expertise and innovation in this field have enabled them to provide customers with cutting-edge color injection molding systems that offer unparalleled precision, efficiency, and performance.

With {Company Name}'s color injection molding technology, manufacturers can achieve a wide range of vibrant and consistent colors in their products, from bold and eye-catching hues to subtle and nuanced shades. This capability is especially valuable in industries such as automotive, consumer goods, electronics, and packaging, where color plays a crucial role in product design and branding.

One of the key advantages of {Company Name}'s color injection molding technology is its ability to meet the high demands of modern manufacturing environments. The company's systems are designed to deliver precise color matching and distribution, ensuring that every part and product meets the strictest quality standards. This level of precision is essential for manufacturers looking to create visually appealing and durable products that stand out in the market.

Moreover, {Company Name}'s color injection molding systems are engineered for efficiency and productivity, helping manufacturers optimize their production processes and reduce overall manufacturing costs. By integrating color directly into the molding process, companies can eliminate the need for post-molding painting or finishing, streamlining their operations and accelerating time to market.

In addition to its technological advancements, {Company Name} prides itself on providing comprehensive support and service to its customers. The company's team of experts works closely with manufacturers to understand their specific color injection molding needs and develop tailored solutions that meet their requirements. From initial consultation and system integration to ongoing maintenance and training, {Company Name} is committed to ensuring the success of its customers' color injection molding projects.

As a result of these capabilities, {Company Name} has earned a strong reputation as a trusted partner for companies seeking to enhance their injection molding capabilities with advanced color solutions. Its color injection molding systems have been widely adopted by leading manufacturers around the world, who rely on the company's expertise to achieve outstanding results in their production processes.

Looking ahead, {Company Name} continues to drive innovation in color injection molding technology, exploring new materials, techniques, and applications to further expand the possibilities for manufacturers. With a dedication to excellence and a deep understanding of the evolving needs of the industry, {Company Name} is poised to remain at the forefront of the color injection molding market, empowering manufacturers to bring their visions to life with precision and efficiency.

Company News & Blog

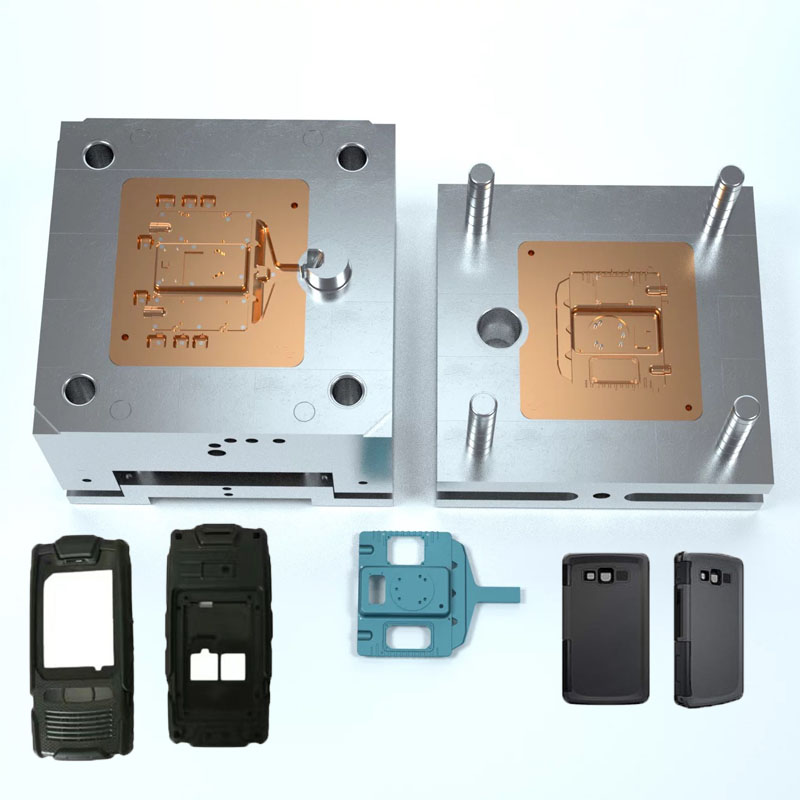

Plastic Injection Mold Supplier for Mould Injection Manufacturing

Plastic injection molding is a vital process in the manufacturing industry, and the quality of molds used in this process directly impacts the final product. As such, choosing the right mold injection supplier is crucial for ensuring the production of high-quality plastic components. One company that has been making waves in the industry is {Company Name}.{Company Name} is a leading provider of high-quality plastic injection molds, offering a wide range of products and services to meet the diverse needs of its clients. With a strong focus on innovation, precision, and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses looking to streamline their manufacturing processes and improve the overall quality of their products.One of the key strengths of {Company Name} is its ability to cater to a variety of industries, including automotive, consumer goods, medical devices, and more. This versatility is made possible by the company's state-of-the-art facilities and a team of skilled professionals who are well-versed in the latest technologies and techniques in mold injection.In addition to its dedication to quality, {Company Name} also emphasizes the importance of sustainability and environmental responsibility in its operations. The company is committed to reducing waste and minimizing its environmental footprint, ensuring that its products are not only top-notch in quality but also eco-friendly.One of the standout offerings from {Company Name} is its range of mould inject supplies for plastic injection molding. These supplies are designed to meet the specific needs of businesses engaged in plastic manufacturing, offering a combination of durability, precision, and cost-effectiveness. Whether clients require molds for small-scale production or large-scale manufacturing, {Company Name} has the expertise and resources to deliver tailored solutions that meet their exact requirements.The company also excels in providing custom mold designs, allowing clients to bring their unique concepts to life with the help of {Company Name}'s engineering and design team. From initial concept to final production, clients can expect seamless collaboration and support at every stage of the mold injection process.{Company Name} takes pride in its commitment to quality control, ensuring that all molds undergo rigorous testing and inspection to guarantee their performance and longevity. This dedication to excellence has earned the company a reputation for delivering superior products that consistently meet and exceed industry standards.Furthermore, {Company Name} places a strong emphasis on customer satisfaction, offering responsive and personalized service to address the unique needs and demands of each client. Its dedication to building long-term partnerships and delivering value-driven solutions has made {Company Name} a go-to choice for businesses seeking reliable and high-quality mold inject supplies.As the demand for high-quality plastic components continues to grow across various industries, {Company Name} remains at the forefront of innovation, providing cutting-edge solutions that empower businesses to thrive in today's competitive market.With its comprehensive range of mold inject supplies, unwavering commitment to quality and customer satisfaction, and a focus on sustainability, {Company Name} is well-positioned to lead the way in the plastic injection molding industry for years to come.In conclusion, {Company Name} stands out as a trusted and reputable supplier of mold inject supplies, offering innovative solutions that cater to the diverse needs of businesses across different industries. With its dedication to quality, sustainability, and customer satisfaction, {Company Name} continues to set the bar high for excellence in the plastic injection molding industry, solidifying its position as a key player in the market.

Increase in Demand for Sustainable Plastic Products Indicates Growing Environmental Awareness

[Insert Date]Plastic Manufacturer Revolutionizes the Industry with Sustainable Solutions[Location] - In a bid to promote sustainability and combat plastic pollution, Plastic Manufacturer, an industry-leading company, has made substantial strides in revolutionizing the plastic manufacturing industry. By integrating innovative practices and adopting eco-friendly initiatives, Plastic Manufacturer has solidified its commitment to producing sustainable and ethically responsible plastic products.Plastic pollution has become a global crisis, with millions of tons of plastic waste finding its way into our oceans and landfills each year. Recognizing the urgent need for change, Plastic Manufacturer has taken a proactive approach to address this issue. This has cemented the company's position as an industry pioneer and a key player in the transition towards sustainable manufacturing practices.At the heart of Plastic Manufacturer's operations lies a deep-rooted commitment to adopting sustainable solutions. With state-of-the-art manufacturing facilities equipped with cutting-edge technology, the company has embraced eco-friendly alternatives to traditional plastic production methods. By incorporating biodegradable and recyclable materials into their manufacturing process, Plastic Manufacturer is actively reducing the environmental impact associated with plastic production.Additionally, Plastic Manufacturer has initiated strategic partnerships with research institutions and environmental organizations to develop innovative solutions. By collaborating with experts in the field, the company aims to create a positive impact and pave the way for a future where sustainability and profitability coexist harmoniously.One of the landmark achievements of Plastic Manufacturer is the introduction of a revolutionary bio-based plastic. Utilizing plant-based materials, this plastic variant offers the same performance characteristics as traditional plastic while being completely biodegradable. This breakthrough has the potential to significantly reduce the environmental impact of plastic waste and create a more sustainable future for generations to come.To ensure the traceability and transparency of its processes, Plastic Manufacturer has implemented an advanced tracking system that allows customers to access detailed information about the origin and composition of their plastic products. This commitment to transparency not only builds trust with customers but also helps raise awareness about the importance of responsible plastic consumption.Furthermore, Plastic Manufacturer places a strong emphasis on recycling and waste management. Through the establishment of recycling initiatives, the company actively promotes the recycling of plastic waste, minimizing its contribution to landfill sites. By encouraging the use of recycled plastic materials, Plastic Manufacturer aims to create a circular economy where plastic waste is repurposed and given new life, instead of ending up as pollution.To drive further change, Plastic Manufacturer actively engages with local communities, government agencies, and non-profit organizations in educational campaigns and initiatives. By emphasizing the importance of individual responsibility in plastic consumption and disposal, the company seeks to create a widespread culture of sustainability.In recognition of its remarkable efforts, Plastic Manufacturer has received several accolades and certifications for its commitment to sustainable practices. Notably, the company has been awarded the Sustainable Manufacturing Excellence Award, signifying its contribution to reducing environmental harm and promoting sustainable development.Looking forward, Plastic Manufacturer envisions a future where sustainability is ingrained within the fabric of the plastic manufacturing industry. The company's unwavering commitment to sustainable solutions, continual research and development, and collaborative partnerships have positioned it as a leader, inspiring other manufacturers to follow suit.Plastic Manufacturer's revolutionary approach not only addresses the environmental challenges posed by plastic pollution but also serves as a testament to the immense possibilities that arise when businesses prioritize sustainability. By aspiring to create a better world, Plastic Manufacturer sets a precedent for other companies to incorporate sustainable practices into their operations, ultimately leading to a greener and healthier planet for future generations.In conclusion, Plastic Manufacturer's dedication to sustainable manufacturing solutions shines a light on the path towards a more sustainable future. Through innovative practices, partnerships, and a strong commitment to transparency, the company is pioneering the transformation of the plastic manufacturing industry. By actively promoting recycling, creating bio-based plastics, and engaging in educational initiatives, Plastic Manufacturer continues to drive change and inspire others to embrace sustainability.

Custom Plastic Injection Mold for Power Cables: All You Need to Know

Plastic Injection Mold For Power Cables Strengthening {Company's} Commitment to Quality and Innovation{City, State, Date} - {Company} is proud to announce the introduction of a state-of-the-art plastic injection mold for power cables. This new addition to the company's production capabilities highlights {Company's} continued commitment to delivering high-quality and innovative solutions to its customers.The plastic injection mold for power cables is designed to meet the growing demand for durable and reliable power cables in various industries, including automotive, industrial, and residential applications. With this new mold, {Company} will be able to produce power cables that meet the highest industry standards for performance and reliability.{Company} has a long-standing reputation for excellence in the manufacturing of power cables, and the introduction of this new plastic injection mold further solidifies its position as a leader in the industry. The mold is equipped with advanced technology and precision engineering, allowing for the production of power cables with exceptional strength, durability, and resistance to environmental factors.In addition to enhancing the quality of its products, {Company} is also focused on the environmental impact of its operations. The new plastic injection mold for power cables is designed to minimize material waste and energy consumption, aligning with {Company's} sustainability goals. By implementing eco-friendly manufacturing practices, {Company} is demonstrating its dedication to reducing its carbon footprint and contributing to a more sustainable future.{Company's} dedication to innovation and excellence is further demonstrated through its investment in research and development. The development of the plastic injection mold for power cables is the result of extensive research and testing, ensuring that the final product meets the rigorous standards set by {Company}. This commitment to continuous improvement allows {Company} to adapt to evolving market demands and stay ahead of the competition.The plastic injection mold for power cables is just one example of {Company's} ongoing efforts to expand its product offerings and deliver solutions that meet the diverse needs of its customers. By offering a comprehensive range of power cables and related products, {Company} aims to be the go-to partner for businesses seeking quality, reliability, and innovation in their supply chain.{Company} has a rich history of serving customers across various industries, including automotive, aerospace, telecommunications, and more. The addition of the plastic injection mold for power cables further strengthens {Company's} position as a trusted supplier and partner to companies of all sizes and sectors.As demand for power cables continues to grow, {Company} is well-positioned to meet the needs of its customers with the introduction of the plastic injection mold. With this new capability, {Company} is poised to play a significant role in shaping the future of power cable manufacturing and contributing to the advancement of technology across industries.The introduction of the plastic injection mold for power cables is a testament to {Company's} unwavering dedication to quality, innovation, and sustainability. As the company continues to expand its capabilities and product offerings, customers can expect nothing less than excellence from {Company}.For more information about {Company} and its plastic injection mold for power cables, please visit {company website} or contact {company representative} at {contact information}.In conclusion, the introduction of the plastic injection mold for power cables is a significant milestone for {Company} and demonstrates its commitment to delivering high-quality and innovative solutions to its customers. With this new capability, {Company} is poised to meet the growing demand for power cables and play a leading role in shaping the future of the industry.

Pc Plastic Injection Mould Display Cover: A Comprehensive Guide

Title: Revolutionary PC Plastic Injection Mould Display Cover Redefines Durability and Efficiency in the Electronics IndustryIntroduction:In the dynamic landscape of the electronics industry, innovation has always been a driving force that shapes and propels businesses forward. Demonstrating a commitment to delivering cutting-edge solutions, [Company Name], a renowned leader in the field of plastic injection molding, has recently launched its groundbreaking PC Plastic Injection Mould Display Cover. This revolutionary product is destined to redefine durability and efficiency, making waves across the industry.The PC Plastic Injection Mould Display Cover is poised to address key challenges faced by the electronics sector, offering incredible mechanical properties, superior heat resistance, and enhanced impact resistance. Designed with impeccable precision, this display cover is created using state-of-the-art plastic injection molding techniques, resulting in a product that is both visually appealing and highly functional.Body:1. Durability and Strength:The PC Plastic Injection Mould Display Cover revolutionizes the electronic device protection landscape by providing unparalleled durability and strength. Manufactured using polycarbonate, a material known for its robust properties, this cover surpasses traditional options currently available on the market. It provides exceptional resistance to scratches, abrasions, and impacts, ensuring the longevity of electronic devices. By shielding delicate displays from accidental drops, harsh environmental conditions, and everyday wear and tear, the cover minimizes the need for costly repairs or replacements, thereby saving both time and resources for end-users.2. Enhanced Heat Resistance:Heat management is a critical aspect in the electronics industry, especially with the increasing processing power and component density of modern devices. The PC Plastic Injection Mould Display Cover possesses outstanding heat-resistant properties, reducing the risk of overheating and ensuring optimal device performance. Equipped with advanced ventilation systems and engineered to dissipate heat effectively, this innovative cover mitigates the potential for heat-related malfunctions. Users can now have peace of mind, knowing that their devices, equipped with this remarkable cover, can endure prolonged usage without compromising efficiency.3. Superior Impact Resistance:One of the common concerns for electronic devices is their vulnerability to accidental damage caused by impacts, drops, or collisions. The PC Plastic Injection Mould Display Cover excels in this area, offering unmatched impact resistance. By employing cutting-edge injection molding techniques, the cover can effectively reduce the impact shock by dispersing it evenly across its surface. This unique feature acts as a protective shield, safeguarding vital internal components and preventing shattered screens in case of accidents. The superior impact resistance provided by this display cover brings reassurance to users, enabling them to confidently use their electronic devices without fear of damage.4. Precision Engineering and Design:The PC Plastic Injection Mould Display Cover showcases the pinnacle of precision engineering and design. [Company Name], renowned for its expertise in plastic injection molding, strategically combines its industry-leading knowledge with the latest technology to create a display cover that seamlessly integrates with various device models. Through meticulous research and development, careful attention is given to ensuring an ergonomic design, guaranteeing an optimal user experience. The precisely engineered fit and finish not only enhance the aesthetics of the device but also prevent dust ingress, providing a clean and seamless display.Conclusion:With the launch of the PC Plastic Injection Mould Display Cover, [Company Name] has set a new standard in the electronics industry. This revolutionary product represents a remarkable leap forward in terms of durability, heat resistance, and impact resistance. Through their commitment to innovation, the company has further solidified its position as a leader in the field of plastic injection molding. As demand for cutting-edge protection solutions continues to rise, the remarkable qualities of this PC Plastic Injection Mould Display Cover are poised to reshape the electronics industry and revolutionize how devices are safeguarded.

Top Benefits of Customized ABS/Plastic Injection Molding Revealed

Customized ABS/Plastic Injection Molding[Company Name], a leading provider of innovative manufacturing solutions, has announced the launch of their new service for customized ABS/plastic injection molding. With their state-of-the-art facilities and expertise in the field, the company is set to revolutionize the industry by providing tailored solutions for various applications.ABS (Acrylonitrile Butadiene Styrene) and plastic injection molding are widely used in numerous industries, including automotive, electronics, consumer goods, and more. These materials offer exceptional mechanical properties, excellent impact resistance, and the ability to be molded into intricate shapes. They are highly sought after due to their durability, versatility, and cost-effectiveness.With the introduction of their customized ABS/plastic injection molding service, [Company Name] aims to cater to the specific needs of their clients. By utilizing advanced manufacturing technologies and techniques, they can deliver precision-molded parts that meet the highest industry standards. The company's team of skilled engineers and designers work closely with the clients to understand their requirements and provide tailored solutions that match their unique specifications.[Company Name] is equipped with cutting-edge injection molding machines that can handle a wide range of part sizes and complexities. Their state-of-the-art facilities are equipped with automated systems and quality control processes to ensure the production of flawless components. This enables the company to offer a comprehensive suite of services, including prototyping, design optimization, tooling, and production.One of the key advantages of ABS/plastic injection molding is its ability to produce parts with detailed features and complex geometries. This makes it well-suited for various industries where intricate parts are essential. With their expertise in engineering polymers, [Company Name] can provide solutions for a diverse range of applications, including automotive interior components, electrical housings, medical devices, and more.In addition to ABS, [Company Name] offers a wide selection of materials that can be used in injection molding. From common thermoplastics like polypropylene and polystyrene to more specialized materials such as polycarbonate and nylon, they can meet the specific requirements of each project. The company also takes into consideration factors such as cost-effectiveness, sustainability, and material performance to ensure optimal results.With their commitment to innovation and customer satisfaction, [Company Name] has built a reputation for delivering high-quality products and services. They have a strong track record of working with clients from various industries, ranging from small businesses to multinational corporations. Their expertise, combined with their advanced manufacturing capabilities, positions them as a trusted partner for all injection molding needs.As the demand for custom injection molding continues to grow, [Company Name] is prepared to meet the evolving needs of their clients. Their customized ABS/plastic injection molding service offers a cost-effective and efficient solution for producing high-quality parts. By leveraging their expertise and state-of-the-art facilities, they can help businesses bring their ideas to life and stay ahead in a competitive market.[Company Name]'s commitment to excellence, innovation, and customer satisfaction sets them apart in the industry. With their new service for customized ABS/plastic injection molding, they are well-positioned to serve a wide range of industries and deliver tailored solutions that meet the unique requirements of each project. Whether it's a simple prototype or a complex production run, [Company Name] has the capabilities to provide exceptional results.

Affordable Plastic Injection Mould: Cost-effective Solution for Your Needs

Cheap Plastic Injection Mould: Revolutionizing Manufacturing IndustriesIn today's globalized world, manufacturing industries play a vital role in driving economic growth. The ability to produce high-quality and cost-effective products is crucial for businesses to remain competitive. In this regard, plastic injection moulding has emerged as a revolutionary manufacturing technique that combines efficiency, affordability, and versatility. One company at the forefront of this industry is [removed brand name], consistently delivering top-notch plastic injection moulds to meet the diverse needs of various sectors.With a commitment to innovation and customer satisfaction, [removed brand name] has established itself as a reliable partner for businesses seeking bespoke plastic injection moulding solutions. By harnessing cutting-edge technologies and state-of-the-art machinery, the company ensures the production of high-quality moulds with consistent precision and accuracy. Their team of experienced engineers and designers work closely with clients to understand their requirements and develop customised moulds that meet their unique specifications.One of the key advantages of plastic injection moulding lies in its cost-effectiveness. Plastic injection moulds are relatively inexpensive to manufacture compared to other moulding techniques, making them ideal for small to large-scale productions. This cost advantage results from the ability to produce multiple products simultaneously using a single mould, significantly increasing production efficiency and reducing production costs. Additionally, the ability to recycle and reuse plastic materials further contributes to cost savings and promotes sustainable manufacturing practices.Furthermore, plastic injection moulds offer unparalleled versatility, making them suitable for a wide range of industries. From automotive to electronics, medical devices to consumer goods, plastic injection moulds can be tailored to meet the specific needs of any sector. With the ability to produce intricate and complex shapes, plastic injection moulds provide endless design possibilities, allowing businesses to create unique and visually appealing products. Moreover, the inherent durability and strength of plastic materials make them ideal for applications that require resistance to impact, corrosion, or harsh environmental conditions.In addition to cost-effectiveness and versatility, plastic injection moulding offers significant time savings in the manufacturing process. Unlike traditional manufacturing techniques, which require multiple steps and lengthy production cycles, plastic injection moulding enables rapid prototyping and quick production turnovers. This accelerated production speed not only reduces time-to-market but also allows businesses to respond swiftly to market demands, gaining a competitive advantage over their rivals.[removed brand name], with its unwavering commitment to excellence, has been a driving force in promoting the advantages of plastic injection moulding across industries. By continuously investing in research and development, the company remains at the forefront of technological advancements in moulding techniques. This commitment to innovation has established [removed brand name] as a trusted partner, providing customers with top-quality moulds that exceed their expectations.Looking ahead, the future of plastic injection moulding seems promising. As industries continue to embrace the advantages of this manufacturing technique, demand for high-quality moulds will inevitably increase. [removed brand name], well-poised to meet this growing demand, will continue to push boundaries and set new industry standards. By harnessing the power of cheap plastic injection moulds, businesses can transform their production processes, reduce costs, and revolutionize their respective industries.

Top Quality Plastic Injection Wall Plug Mould: A Practical Choice for Secure Wall Mounting

Plastic Injection Wall Plug Mould Revolutionizes Home Improvement Industry[City, Date] - The home improvement industry has taken a significant leap forward with the development of the latest innovation in plastic injection wall plug moulds. This revolutionary technology is set to transform the way people tackle everyday repairs and installations around their homes. With its superior strength, durability, and ease of use, this groundbreaking product is expected to become a game-changer in the market.Traditionally, wall plugs have been made from materials such as wood or metal, which often require drilling and hammering. However, the introduction of plastic injection wall plug moulds eliminates the need for these labor-intensive methods. These moulds allow users to effortlessly insert wall plugs into various surfaces, greatly simplifying the process of mounting shelves, hanging pictures, or installing light fixtures.One of the key advantages of plastic injection wall plug moulds is their exceptional strength. Unlike traditional wall plugs, which can become loose over time, these new wall plugs ensure a secure hold in walls and other surfaces. This means that homeowners can have peace of mind, knowing that their installations are reliable and stable.Another prominent feature of plastic injection wall plug moulds is their durability. Made from high-quality materials, these new plugs are built to last. They can withstand heavy loads and are resistant to corrosion, ensuring they remain intact for extended periods. By using plastic injection wall plug moulds, homeowners can be confident that their installations will remain in place for years to come.In addition to their strength and durability, plastic injection wall plug moulds offer unrivaled convenience. With their user-friendly design, these plugs can be easily inserted into walls without the need for drilling. This eliminates the hassle of finding the right size drill bit or making sure the hole is properly aligned. Now, anyone can effortlessly carry out home improvement tasks, regardless of their experience level.The introduction of plastic injection wall plug moulds has not only impacted homeowners but also professionals in the construction industry. Builders, contractors, and electricians alike have recognized the benefits of this revolutionary product. With its versatility and efficiency, the moulds have dramatically improved the speed and ease with which professionals can complete their projects. This has resulted in cost savings and increased productivity across the industry.{} is at the forefront of this groundbreaking innovation. As a leading manufacturer and distributor of plastic injection wall plug moulds, {} is committed to delivering the highest quality products to its customers. With a strong focus on research and development, {} continuously introduces cutting-edge solutions that redefine the industry standards.At {}'s state-of-the-art manufacturing facility, top-notch engineers and technicians work tirelessly to create moulds that meet the ever-evolving needs of consumers. With strict quality control measures in place, every mould undergoes rigorous testing to ensure exceptional performance and reliability. Backed by a dedicated customer support team, {} provides comprehensive assistance to its clients, offering guidance and expert advice throughout their home improvement journeys.Looking ahead, the future of plastic injection wall plug moulds seems promising. As the demand for effortless and reliable home improvement solutions continues to grow, the market for these innovative moulds is expected to expand rapidly. With {} pioneering developments, homeowners and professionals can expect greater convenience, efficiency, and effectiveness in their projects.The era of struggle with wall plugs is over. Thanks to plastic injection wall plug moulds, repairs and installations have never been easier. Whether you are a DIY enthusiast or a professional in the industry, {}'s superior moulds are set to transform the way you approach home improvement forever.About {}:{} is a leading manufacturer and distributor of plastic injection wall plug moulds. With a commitment to innovation and customer satisfaction, the company aims to revolutionize the home improvement industry. Backed by cutting-edge technology and a team of experts, {} provides unparalleled products and support to its clients, setting new benchmarks for quality and reliability.

A complete guide to injection molding techniques

Injection Mold Or Injection Molding is a widely used manufacturing process for creating a variety of products, from plastic components to metal parts. It involves injecting molten material into a mold, which is then cooled and solidified to form the desired shape. This process is used in a wide range of industries, including automotive, aerospace, electronics, and medical devices.One company that has excelled in the field of Injection Mold Or Injection Molding is {}. {} has been at the forefront of innovation and excellence in this industry for over twenty years. With a strong emphasis on quality, precision, and efficiency, {} has established itself as a leading provider of injection molding services.Injection Mold Or Injection Molding process at {} is a highly controlled and precise operation. The company utilizes state-of-the-art equipment and advanced technologies to ensure that every product meets the highest standards of quality and accuracy. With a team of experienced engineers and technicians, {} is able to provide custom solutions for a wide range of manufacturing needs.{} is capable of handling a wide variety of materials, including various types of plastics, metals, and composites. This allows the company to create custom solutions for a diverse set of industries and applications. Whether it's producing intricate plastic components for the automotive industry or creating precision metal parts for aerospace applications, {} has the expertise and capabilities to deliver high-quality products.In addition to its manufacturing capabilities, {} also offers design and engineering services to help clients bring their ideas to life. With a focus on innovation and collaboration, the company works closely with its clients to develop custom solutions that meet their specific requirements. Whether it's creating a new product from scratch or optimizing an existing design for manufacturability, {} has the expertise and resources to make it happen.One of the key advantages of Injection Mold Or Injection Molding is its ability to produce high volumes of parts with excellent consistency and repeatability. This makes it an ideal solution for mass production and large-scale manufacturing needs. Whether it's producing small, intricate components or large, complex parts, {} has the capacity and expertise to deliver reliable, high-quality products on a consistent basis.As a provider of injection molding services, {} is committed to sustainability and environmental responsibility. The company utilizes efficient manufacturing processes and sustainable materials to minimize its environmental impact. This commitment to sustainability not only benefits the environment, but also helps clients meet their own sustainability goals and requirements.With a strong track record of delivering high-quality products and a commitment to innovation and excellence, {} is well-positioned to continue its leadership in the field of Injection Mold Or Injection Molding. As the demand for custom manufacturing solutions continues to grow, {} is dedicated to providing the highest level of service and quality to its clients.In conclusion, Injection Mold Or Injection Molding is a critical manufacturing process used in a wide range of industries. {} has established itself as a leading provider of injection molding services, with a strong emphasis on quality, precision, and efficiency. With a focus on innovation and collaboration, {} is well-equipped to meet the diverse needs of its clients and deliver high-quality products on a consistent basis.

The Advantages of Small Plastic Injection Moulds

Plastic Injection Mould Small is in high demand in many industries due to its ability to produce intricate and precise plastic components. The small size of these molds makes them ideal for producing small plastic parts, which are used in various consumer products, medical devices, automotive components, and electronic devices. This growing demand for small plastic injection molds has led to the development of advanced manufacturing techniques to meet the industry's requirements.The small plastic injection mold market is dominated by several key players who have a long history of providing high-quality products to their customers. These companies have a deep understanding of the intricacies involved in creating small plastic injection molds and have a proven track record of delivering top-notch products. One such company is {}, which has been a leader in the plastic injection molding industry for many years.{} is renowned for its expertise in designing and manufacturing small plastic injection molds. The company has a team of highly skilled engineers and designers who work tirelessly to create innovative and efficient mold designs. With state-of-the-art manufacturing facilities and cutting-edge technology, {} is able to produce small plastic injection molds that meet the exact specifications of its clients. The company has earned a reputation for delivering high-quality molds that are durable, reliable, and cost-effective.The small plastic injection molds produced by {} are used in a wide range of industries, including automotive, electronics, medical, and consumer goods. These molds are capable of producing complex geometries, tight tolerances, and intricate details, making them ideal for manufacturing small plastic parts. {} takes pride in its ability to provide customized mold solutions to meet the specific needs of its diverse clientele. The company works closely with its customers to understand their requirements and deliver molds that exceed their expectations.One of the key factors that set {} apart from its competitors is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of the curve and incorporate the latest advancements in mold design and manufacturing. This dedication to innovation has enabled {} to develop cutting-edge small plastic injection molds that deliver exceptional performance and reliability.In addition to its technical expertise, {} is also known for its outstanding customer service. The company has a team of dedicated professionals who are committed to providing exceptional support to its clients throughout the mold design and manufacturing process. {} understands the importance of fostering strong relationships with its customers and works tirelessly to ensure that their needs are met with the highest level of professionalism and care.As the demand for small plastic injection molds continues to grow, {} remains at the forefront of the industry, providing innovative solutions to its clients. The company's relentless pursuit of excellence and dedication to customer satisfaction have solidified its position as a trusted partner for small plastic injection mold needs.In conclusion, plastic injection molding is an essential manufacturing process that plays a critical role in various industries. The demand for small plastic injection molds continues to rise, driving the need for advanced manufacturing techniques and innovative solutions. With its unparalleled expertise, commitment to innovation, and exceptional customer service, {} is well-positioned to meet the evolving needs of the small plastic injection mold market and remain a leader in the industry.

High-quality Injection Molding Services for ABS Plastic Parts

Title: Pioneering ABS Plastic Parts Injection Molding Services Revolutionize Manufacturing IndustryIntroduction:In a rapidly evolving world driven by technological advancements, companies are continually seeking innovative ways to enhance their manufacturing processes. One such company, which for confidentiality purposes we shall refer to as "ABC Manufacturing," has emerged as a pioneer in revolutionizing the production of ABS plastic parts through their groundbreaking injection molding services. With an unwavering commitment to quality, efficiency, and client satisfaction, ABC Manufacturing has become a leading name in the industry.I. Overview of ABS Plastic Parts Injection Molding Services:Injection molding is a widely acclaimed manufacturing technique that involves creating complex and durable plastic parts through the injection of molten material into a mold cavity. ABS plastic, known for its exceptional strength, impact resistance, and heat resistance, has become a sought-after material for a variety of applications, ranging from automotive components to electronics and consumer goods.ABC Manufacturing employs state-of-the-art injection molding machinery, operated by a highly skilled workforce, to produce ABS plastic parts of exceptional quality. Their commitment to incorporating cutting-edge technology allows for precision in design, resulting in products that meet the most stringent industry standards.II. Advantages of ABS Plastic Parts Injection Molding:1. Versatility: The injection molding process enables the creation of highly intricate and complex designs with precise detailing, meeting the diverse needs of industries such as automotive, electronics, and medical equipment.2. Cost-effective Production: With the ability to create large volumes of parts in a relatively short span, ABS plastic parts injection molding offers a cost-effective solution for mass production. This ensures the reduction of production costs and allows businesses to stay competitive in the market.3. Enhanced Durability: ABS plastic possesses excellent mechanical properties, including high strength and impact resistance. These characteristics make it an ideal choice for manufacturing parts that require durability and longevity.4. Aesthetically Appealing: Injection molding provides a smooth and uniform finish, making ABS plastic parts visually appealing. This allows businesses to enhance the branding and marketability of their products.III. ABC Manufacturing's Unique Approach:1. Extensive Experience: With several years of experience in the industry, ABC Manufacturing has amassed a wealth of knowledge and expertise in delivering customized ABS plastic parts. Their team of engineers collaborates closely with clients to understand their specific requirements, ensuring the production of parts that perfectly match their needs.2. Cutting-edge Technology: ABC Manufacturing constantly updates their production processes to incorporate the latest technological advancements. Through advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software, they ensure precision in part geometry and dimensional accuracy. This commitment to innovation enables them to produce high-quality products efficiently.3. Quality Assurance: ABC Manufacturing places a strong emphasis on quality control and assurance. They have implemented strict inspection protocols at every stage of the production process, guaranteeing consistently excellent results. Furthermore, their commitment to sustainability extends to the use of environmentally friendly ABS materials, ensuring an eco-conscious approach to manufacturing.IV. Market Impact and Future Prospects:ABC Manufacturing's ABS plastic parts injection molding services have made a significant impact on the manufacturing industry. Their innovative approach has enabled companies to enhance their production efficiency, reduce costs, and deliver top-notch products to the market. As demand for ABS plastic parts continues to grow, ABC Manufacturing is strongly positioned to maintain its leading role in the industry.Conclusion:ABC Manufacturing's ABS plastic parts injection molding services have reimagined the manufacturing landscape. Their commitment to excellence, unwavering dedication to technological innovation, and relentless pursuit of customer satisfaction have propelled them to the forefront of the industry. Through their groundbreaking production processes, they continue to redefine what is possible in the world of ABS plastic parts manufacturing.