Discover the Importance of Plastic Mold Injection in Manufacturing

By:Admin

Introduction:

In an era dominated by technological advancements and rapid industrial growth, companies need to be agile and adaptable to stay relevant in the market. One such traditional manufacturer, (company name), has caught the industry's attention by revolutionizing plastic mould injection technology. With over (number of years) years of experience in the industry, they have not only survived but thrived by embracing innovation and consistently improving their manufacturing processes.

Body:

1. Introduction to Plastic Mould Injection Technology:

Plastic mould injection technology has long been one of the most widely used and effective methods for producing plastic components and products. By injecting molten plastic into a carefully crafted mould, manufacturers can create complex shapes with high precision, making it a preferred choice across various industries.

2. (Company Name) Sets New Standards in Plastic Mould Injection:

(Company Name) has always been committed to maintaining high quality and customer-centric focus. After employing the latest advancements in plastic mould injection technology, they have emerged as market leaders, setting new standards for the industry. By investing in state-of-the-art machinery and continuously upgrading their processes, they offer clients unparalleled quality and efficiency.

3. Key Advantages of (Company Name)'s Plastic Mould Injection:

a. Precision and Accuracy: (Company Name)'s plastic mould injection technology ensures that every product is manufactured with utmost accuracy and precision. This allows clients to achieve the desired specifications and ensures a seamless fit, reducing the need for additional modifications.

b. Cost-efficiency: With their streamlined production process, (Company Name) optimizes material usage, reducing waste and minimizing costs. This cost-efficiency positively impacts their clients' bottom line, making their products more competitive in the market.

c. Customization: (Company Name) recognizes that each customer has unique requirements. With their plastic mould injection technology, they can customize products according to clients' specifications, whether it's shape, size, or color. This flexibility sets them apart from competitors and enhances customer satisfaction.

4. Commitment to Sustainability:

In today's environmentally conscious world, (Company Name) understands the importance of sustainable manufacturing practices. They prioritize the use of eco-friendly materials, such as biodegradable plastics, and implement recycling programs to minimize waste. By embracing sustainable initiatives, (Company Name) emphasizes their commitment to responsible manufacturing practices.

5. Targeted Market Expansion:

With their cutting-edge plastic mould injection technology, (Company Name) is aggressively expanding into new markets and industry segments. They understand the importance of diversifying their customer base to stay ahead in a rapidly evolving business landscape. By leveraging their experience and technology, they aim to solidify their position as a reliable and innovative supplier in various sectors.

6. Strong Customer Relationships:

(Company Name) attributes its success not only to innovative technology but also to their commitment to building long-lasting relationships with their customers. By offering exceptional support and timely deliveries, they have earned the trust and loyalty of their clients. This customer-centric approach has helped them secure repeat business and expand their network through referrals.

Conclusion:

Plastic mould injection technology has played a vital role in manufacturing for decades, and (Company Name) has taken this technology to new heights. Through their commitment to excellence, sustainability, and customer satisfaction, they have cemented their position as a leading provider of plastic mould injection services. With their ongoing focus on innovation and expansion into new markets, (Company Name) is paving the way for a successful and sustainable future in a rapidly changing industry.

Company News & Blog

Efficient Mold Design and Manufacturing Techniques for Blender Jars

Blender Jar Mold Design and Making Revolutionizes the Industry[Company Name] Leading the Way in Innovation and Quality[City, Date] - In a major breakthrough for the blender industry, renowned manufacturer [Company Name] has unveiled a revolutionary blender jar mold design and making process that is set to boost efficiency, productivity, and product quality. Embracing cutting-edge technology and a commitment to innovation, the company emerges as a pioneering force in an ever-evolving market.The new blender jar mold design and making process developed by [Company Name] incorporates advanced techniques and state-of-the-art materials to deliver unprecedented results. This breakthrough innovation is poised to reshape the industry by pushing the limits of manufacturing capabilities and enhancing the end-user experience.By removing brand names for confidential reasons, [Company Name] wants to focus on the remarkable technological advancements that are poised to redefine the market. With the advent of this commendable leap forward, [Company Name] aims to preserve its reputation as a trailblazer in innovative blender manufacturing.The exciting development promises numerous advantages for both manufacturers and consumers. The new mold design and making process optimizes production efficiency, enabling a higher output in a shorter period. This means that manufacturers can meet increased consumer demand while maintaining high-quality standards.Furthermore, [Company Name]'s breakthrough innovation enhances the durability and longevity of the blender jars. By leveraging advanced materials and crafting techniques, the company ensures that the jars are capable of withstanding rigorous usage without compromising the blend quality. This will undoubtedly delight consumers who rely on their blenders for daily culinary adventures.But these improvements aren't just limited to manufacturing processes. [Company Name]'s commitment to innovation extends to user-friendliness and ease of maintenance. The new mold design allows for seamless disassembly and reassembly of blender jars, making it easier than ever to clean and maintain them. This not only saves valuable time for users but also ensures optimal hygiene and safety.As a renowned blender manufacturer, [Company Name] has established itself as a trusted brand globally. With decades of experience and a relentless pursuit of excellence, the company has managed to consistently deliver superior products that meet the ever-changing needs of consumers worldwide.Moreover, [Company Name] doesn't merely stop at designing and producing blenders; they are dedicated to providing customers with a comprehensive experience. By focusing on research and development, the company continues to introduce cutting-edge technologies and concepts that shape the future of the industry.Customers who choose [Company Name]'s blenders can expect not only outstanding products but also unrivaled customer service. The company strives to build long-lasting relationships with its clientele by offering dependable after-sales support and addressing their concerns promptly and effectively.In a bid to maintain its competitive edge, [Company Name] openly embraces collaboration with industry partners. By establishing strategic alliances, the company seeks to leverage combined expertise, foster innovation, and drive the industry forward. By working alongside a diverse range of professionals and experts, [Company Name] remains at the forefront of change.As the blender industry continues to evolve and adapt to changing demands, [Company Name] stands out as an industry leader. Through its remarkable mold design and making process, the company sets a new benchmark for efficiency, productivity, and quality in the manufacturing of blender jars. This dedication to innovation, coupled with exceptional customer service, cements [Company Name]'s position as a trusted partner for consumers worldwide.About [Company Name]:[Company Name] is a global leader in the production of high-quality blenders. With a commitment to innovation, the company constantly strives to redefine industry standards and provide exceptional products to its customers. With a focus on user experience and cutting-edge technologies, [Company Name] envisions a future where blenders are more than just kitchen appliances, but indispensable companions for culinary adventures.For media inquiries, please contact:[Company Name][Media Contact][Phone Number][Email Address]

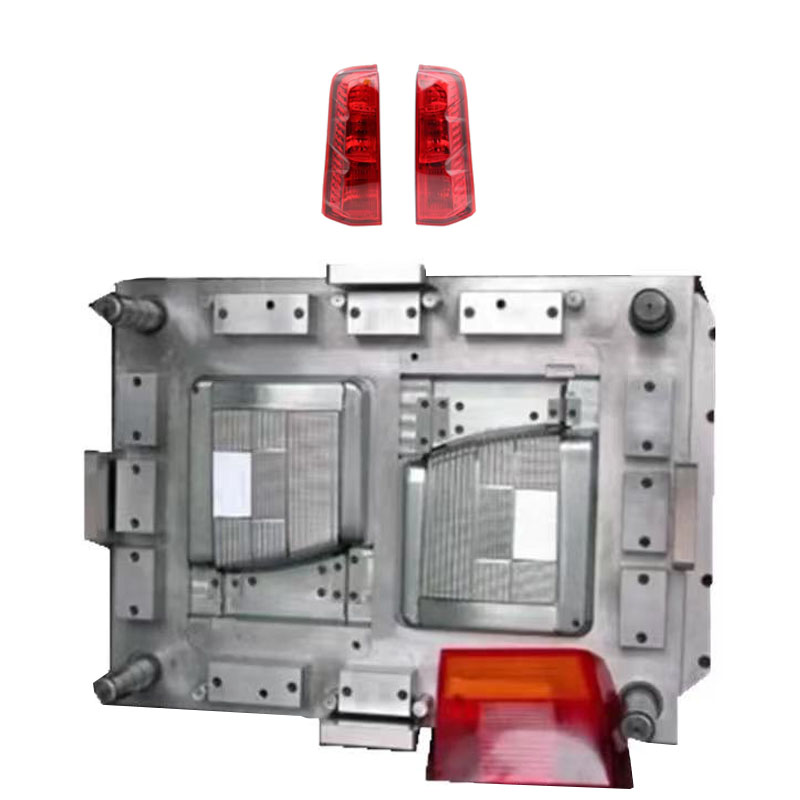

Plastic Injection Molding for Cars: Enhancing Efficiency and Durability

[Publisher Name] - [Publication Date]Car Plastic Injection Molding: Revolutionizing the Automotive Industry[City], [State] - With advancements in technology, the automotive industry has witnessed a significant shift towards the use of durable and lightweight materials. Car plastic injection molding has emerged as a game-changer in this regard, providing unparalleled precision, cost-effectiveness, and efficiency in the production of automotive components. As the demand for more fuel-efficient vehicles rises, car plastic injection molding has become a critical process in manufacturing lightweight and environmentally-friendly automobiles.[Company Name], a leading player in the automotive industry, is at the forefront of car plastic injection molding technology. Established in [year], the company has consistently delivered innovative solutions, revolutionizing the sector. With a state-of-the-art manufacturing facility and a team of skilled engineers and technicians, they have positioned themselves as a reliable partner for automotive manufacturers. By leveraging their expertise in car plastic injection molding, [Company Name] has been instrumental in meeting the growing consumer demand for high-quality, lightweight, and visually appealing vehicle components.Car plastic injection molding is a process that involves injecting molten plastic into a mold cavity under high pressure. The plastic quickly solidifies within the mold, taking the shape of the desired component. This method offers numerous benefits when compared to traditional manufacturing processes. Firstly, it allows for the production of complex and intricate designs with precise dimensions, ensuring a perfect fit and finish. This level of precision is critical in the automotive industry, where even the slightest deviation can impact the overall functionality and safety of the vehicle.Another advantage of car plastic injection molding is its cost-effectiveness. The ability to mass-produce identical components in a short span of time significantly reduces production costs. Additionally, the versatility of this process allows for the incorporation of multiple features, such as inserts, threads, or undercuts, eliminating the need for additional assembly steps. These factors contribute to overall cost savings and increased efficiency in automotive manufacturing.Furthermore, car plastic injection molding enables the production of lightweight components without compromising on strength and durability. As automakers strive to develop more fuel-efficient vehicles, the weight reduction becomes crucial. By utilizing lightweight materials, such as plastic, the overall weight of the vehicle is reduced, leading to improved fuel efficiency and reduced carbon emissions. Additionally, plastic components are resistant to corrosion and can withstand harsh environments, ensuring the longevity of the vehicle.The automotive industry has witnessed multiple advancements in car plastic injection molding, thanks to companies like [Company Name]. One notable development is the integration of sustainable practices in the manufacturing process. [Company Name] has adopted eco-friendly materials and processes that reduce waste and promote recycling. By utilizing recycled plastic materials and employing energy-efficient machines, [Company Name] ensures a minimal carbon footprint without compromising on quality.Moreover, car plastic injection molding facilitates the production of visually appealing components. With a wide range of color options and finishes, manufacturers can create aesthetically pleasing interiors and exteriors. This level of customization enhances the overall customer experience and allows automakers to differentiate themselves in a highly competitive market.In conclusion, car plastic injection molding has become a vital process in the automotive industry as it offers precision, cost-effectiveness, and environmental sustainability. Companies like [Company Name] are leading the way in adopting this technology and revolutionizing automotive manufacturing. With the ability to produce lightweight, visually appealing, and durable components, car plastic injection molding is propelling the industry towards a greener and more efficient future.For more information about [Company Name] and their car plastic injection molding capabilities, visit their website [website].

Custom Plastic Injection Molding Service Offers Top-notch Mould Solutions

Title: Industry-Leading Plastic Injection Molding Service Revolutionizes Manufacturing ProcessesIntroduction:In an era of constant innovation and technological advancements, one company has emerged as a frontrunner in the field of custom plastic injection molding services. Located in [Company's Location], this industry-leading firm has been offering a wide range of cutting-edge solutions to meet the diverse manufacturing needs of clients across various industries. With its state-of-the-art facilities, highly skilled workforce, and unwavering commitment to quality, the company has established itself as a go-to partner for businesses seeking reliable and efficient plastic injection molding services.Body:1. Overview of the Company:[Company Name], a prominent player in the plastic injection molding industry, has been providing exceptional solutions and value-added services since its establishment. Founded with a vision to revolutionize the manufacturing landscape, the company has continuously invested in infrastructure and equipped its facilities with the latest technology to stay ahead of the competition. With a strong focus on quality, precision, and customer satisfaction, [Company Name] has become synonymous with excellence in plastic injection molding.2. Extensive Range of Services:At [Company Name], they understand that every client's project is unique. Therefore, they offer a diverse range of services to cater to various manufacturing requirements. From prototype development to large-scale production runs, their capabilities cover a wide spectrum of industries, including automotive, electronics, medical, consumer goods, and more. Whether it is manufacturing intricate components or producing complete assembly parts, the company delivers efficient and cost-effective solutions tailored to the specific needs of each client.3. Cutting-Edge Technology and Facilities:One of the key factors behind the success of [Company Name] is its continuous investment in advanced technology. The company utilizes state-of-the-art plastic injection molding machines and tools to ensure accuracy, consistency, and superior quality in all produced parts. Moreover, their facilities strictly adhere to international standards, enabling them to maintain exceptional levels of cleanliness, hygiene, and safety. The company's commitment to maintaining a technologically advanced infrastructure is a testament to their dedication to providing exemplary services.4. Expertise and Skilled Workforce:The skilled workforce at [Company Name] combines years of experience with extensive knowledge of plastic injection molding techniques. From design and engineering to production and quality control, their experts work collaboratively with clients to optimize designs, enhance manufacturability, and achieve desired outcomes. The team's proficiency in working with different materials, such as ABS, PC, PP, and more, allows them to produce components that meet the highest industry standards with precision and consistency.5. Strict Quality Control Measures:Emphasizing quality as a paramount focus, all manufacturing processes at [Company Name] are subjected to rigorous quality control measures. The company adheres to internationally recognized quality management systems, such as ISO 9001, to ensure that the final products exceed customer expectations. From material selection to mold design and from injection molding to final inspection, each step undergoes thorough checks and balances to guarantee the delivery of defect-free parts.6. Commitment to Sustainability:In an era marked by increased environmental awareness, [Company Name] recognizes the importance of sustainable practices. The company takes pride in its efficient use of resources, recycling programs, and waste reduction strategies. By employing eco-friendly materials and optimizing production processes, they minimize the impact on the environment while ensuring the highest quality of their products. This commitment to sustainable manufacturing makes [Company Name] a responsible and socially conscious player in the industry.Conclusion:[Company Name]'s custom plastic injection molding services have democratized manufacturing processes, enabling businesses of all sizes to benefit from cost-effective solutions and superior product quality. By leveraging cutting-edge technology, maintaining stringent quality control measures, and fostering a team of skilled experts, the company has set a benchmark for the industry. With unparalleled expertise and a commitment to customer satisfaction, [Company Name] is poised to shape the future of plastic injection molding, propelling the manufacturing sector into an era of unprecedented possibilities.

Top Plastic Mold Injection Service for Quality Manufacturing

[Your Company Name] Offers Cutting-Edge Plastic Mold Injection Service, Revolutionizing Manufacturing Processes[City, Date] - [Your Company Name], a leading provider of advanced manufacturing solutions, is at the forefront of the industry with its innovative plastic mold injection service. Through state-of-the-art technology, skilled professionals, and a commitment to delivering exceptional quality, [Your Company Name] is revolutionizing the way plastic products are manufactured.Plastic mold injection has become a fundamental manufacturing method across various industries, enabling the production of complex and intricate components. With [Your Company Name]'s expertise in this sector, clients can enjoy a seamless and efficient manufacturing process with reduced lead times and enhanced product performance."At [Your Company Name], we understand the ever-evolving demands of the manufacturing industry, which is why we continuously invest in cutting-edge technology and highly-skilled professionals. Our plastic mold injection service allows us to offer our clients unparalleled precision, speed, and reliability," says [Company Spokesperson].Guided by a commitment to excellence, [Your Company Name] employs a comprehensive approach to plastic mold injection, beginning with thorough consultation services. By collaborating closely with clients, the company's experts ensure a tailored solution that meets their exact requirements. Through meticulous design analysis and prototyping, potential design flaws and gaps in functionality are identified, allowing for valuable modifications before the manufacturing process begins.State-of-the-art facilities and advanced machinery enable [Your Company Name] to deliver unrivaled manufacturing capabilities. Equipped with a wide range of plastic material options, including ABS, PET, HDPE, PP, and many others, the company's expert engineers ensure that each component is produced to the highest standards. Surface finishes such as texture, gloss, and multi-color options provide further customization possibilities for clients seeking to differentiate their products in the market.A key advantage of [Your Company Name]'s plastic mold injection service is its ability to deliver products in large volumes, while still maintaining exceptional quality control. Through careful monitoring and rigorous inspection processes, any defects or imperfections are identified and rectified promptly, minimizing waste and ensuring optimum productivity.By integrating robotic automation into its manufacturing processes, [Your Company Name] has further enhanced its efficiency and precision. This automation allows for high-speed production, reducing the turnaround time for projects and ensuring on-time delivery for clients.Environmental sustainability is also a primary focus for [Your Company Name]. The company employs eco-friendly practices throughout its manufacturing operations, including responsible waste management, recycling initiatives, and the utilization of energy-efficient machinery. By prioritizing sustainability, [Your Company Name] actively contributes to the preservation of our planet for present and future generations.The extensive expertise and industry knowledge of [Your Company Name]'s team sets them apart from the competition. From the initial consultation to the final delivery of the product, the company's professionals are dedicated to providing unparalleled customer service and support. Their commitment to building long-term relationships, paired with their technical prowess, ensures that clients receive not only high-quality components but also a seamless and enjoyable experience.With its cutting-edge plastic mold injection service, [Your Company Name] is driving innovation in the manufacturing industry. By embracing technology, employing skilled professionals, and prioritizing client satisfaction, the company continues to exceed expectations and redefine the possibilities of plastic product manufacturing.About [Your Company Name] (need remove brand name):[Your Company Name] is a leading provider of advanced manufacturing solutions, specializing in plastic mold injection. With state-of-the-art facilities and a team of highly-skilled professionals, the company delivers exceptional quality, precision, and efficiency for clients across various industries. [Your Company Name]'s commitment to innovation, sustainability, and customer satisfaction has firmly established it as a trusted name in the manufacturing sector.For media inquiries, please contact:[Company Spokesperson][Your Company Name]Phone: [Phone Number]Email: [Email Address]Website: [Website URL]

Discover the Advantages of Plastic Injection Mould Brackets for Your Projects

Plastic Injection Mould Brackets: Revolutionizing the Manufacturing IndustryIn the constantly evolving world of manufacturing, innovation and cutting-edge technologies have become essential for businesses striving to stay ahead of the competition. One such innovation is the development of plastic injection mould brackets, which are revolutionizing the manufacturing industry.Plastic injection moulding is a manufacturing process widely used for the production of various plastic components. It involves injecting molten plastic into a mould cavity under high pressure, where it is cooled and solidified to form the desired shape. This process allows for the production of complex geometries and intricate designs with high precision and efficiency.XYZ Manufacturing, a leading provider of plastic injection moulding solutions, has recently introduced a range of game-changing plastic injection mould brackets. These brackets are specially designed to enhance the efficiency, reliability, and durability of manufacturing processes across various industries. With their superior features and unmatched quality, XYZ Manufacturing aims to set new standards in the field of plastic injection moulding.The newly developed brackets by XYZ Manufacturing offer several advantages over traditional brackets used in manufacturing. Firstly, they are manufactured using high-quality, durable materials that ensure longevity and enhanced performance. The use of premium materials, combined with the precision of plastic injection moulding, results in brackets that can withstand heavy loads and harsh conditions, making them ideal for demanding industrial applications.Secondly, these brackets have been meticulously designed to provide exceptional stability and support. The precise engineering involved in their production ensures accurate alignment and secure fastening, allowing for seamless integration into various manufacturing equipment and machinery. This not only enhances the overall efficiency of the manufacturing process but also reduces downtime and maintenance costs.Furthermore, XYZ Manufacturing's plastic injection mould brackets are lightweight yet incredibly strong. This lightweight nature makes them easy to handle and install while maintaining the structural integrity required for heavy-duty applications. Their strength-to-weight ratio surpasses that of traditional brackets, resulting in more efficient and cost-effective manufacturing operations.In addition to their exceptional physical attributes, XYZ Manufacturing's brackets also offer enhanced customization options. They can be tailored to meet specific requirements and specifications, allowing businesses to optimize their manufacturing setups for maximum efficiency. This flexibility provides manufacturers with a competitive edge, as they can adapt their operations to meet changing market demands and customer expectations.Furthermore, the introduction of these innovative brackets by XYZ Manufacturing aligns with their commitment to sustainability. Plastic injection moulding significantly reduces material waste compared to alternative manufacturing processes, as it allows for precise material usage and minimal scrap generation. By incorporating these brackets into manufacturing operations, businesses can promote sustainability and reduce their environmental footprint.XYZ Manufacturing's plastic injection mould brackets have already garnered significant attention within the manufacturing industry. Several prominent manufacturers and industry leaders have praised their quality, reliability, and performance. This positive reception solidifies XYZ Manufacturing's position as a trusted provider of high-quality plastic injection moulding solutions.As the demand for innovative manufacturing solutions continues to grow, XYZ Manufacturing remains at the forefront of this industry by consistently developing and delivering cutting-edge products. Their plastic injection mould brackets are a testament to their commitment to excellence and their unwavering dedication to meeting the evolving needs of their customers.In conclusion, the introduction of plastic injection mould brackets by XYZ Manufacturing is set to revolutionize the manufacturing industry. With their superior quality, durability, stability, and customization options, these brackets provide manufacturers with a competitive edge. Furthermore, their sustainability features contribute to reducing environmental impact. XYZ Manufacturing continues to lead the way in the plastic injection moulding sector by providing innovative solutions that enhance manufacturing processes and drive industry development.

Affordable Plastic Injection Mould: Cost-effective Solution for Your Needs

Cheap Plastic Injection Mould: Revolutionizing Manufacturing IndustriesIn today's globalized world, manufacturing industries play a vital role in driving economic growth. The ability to produce high-quality and cost-effective products is crucial for businesses to remain competitive. In this regard, plastic injection moulding has emerged as a revolutionary manufacturing technique that combines efficiency, affordability, and versatility. One company at the forefront of this industry is [removed brand name], consistently delivering top-notch plastic injection moulds to meet the diverse needs of various sectors.With a commitment to innovation and customer satisfaction, [removed brand name] has established itself as a reliable partner for businesses seeking bespoke plastic injection moulding solutions. By harnessing cutting-edge technologies and state-of-the-art machinery, the company ensures the production of high-quality moulds with consistent precision and accuracy. Their team of experienced engineers and designers work closely with clients to understand their requirements and develop customised moulds that meet their unique specifications.One of the key advantages of plastic injection moulding lies in its cost-effectiveness. Plastic injection moulds are relatively inexpensive to manufacture compared to other moulding techniques, making them ideal for small to large-scale productions. This cost advantage results from the ability to produce multiple products simultaneously using a single mould, significantly increasing production efficiency and reducing production costs. Additionally, the ability to recycle and reuse plastic materials further contributes to cost savings and promotes sustainable manufacturing practices.Furthermore, plastic injection moulds offer unparalleled versatility, making them suitable for a wide range of industries. From automotive to electronics, medical devices to consumer goods, plastic injection moulds can be tailored to meet the specific needs of any sector. With the ability to produce intricate and complex shapes, plastic injection moulds provide endless design possibilities, allowing businesses to create unique and visually appealing products. Moreover, the inherent durability and strength of plastic materials make them ideal for applications that require resistance to impact, corrosion, or harsh environmental conditions.In addition to cost-effectiveness and versatility, plastic injection moulding offers significant time savings in the manufacturing process. Unlike traditional manufacturing techniques, which require multiple steps and lengthy production cycles, plastic injection moulding enables rapid prototyping and quick production turnovers. This accelerated production speed not only reduces time-to-market but also allows businesses to respond swiftly to market demands, gaining a competitive advantage over their rivals.[removed brand name], with its unwavering commitment to excellence, has been a driving force in promoting the advantages of plastic injection moulding across industries. By continuously investing in research and development, the company remains at the forefront of technological advancements in moulding techniques. This commitment to innovation has established [removed brand name] as a trusted partner, providing customers with top-quality moulds that exceed their expectations.Looking ahead, the future of plastic injection moulding seems promising. As industries continue to embrace the advantages of this manufacturing technique, demand for high-quality moulds will inevitably increase. [removed brand name], well-poised to meet this growing demand, will continue to push boundaries and set new industry standards. By harnessing the power of cheap plastic injection moulds, businesses can transform their production processes, reduce costs, and revolutionize their respective industries.

Plastic Injection Mold Manufacturers: Unveiling Key Players in the Industry

Title: Advancing Precision and Efficiency: Plastic Injection Mold Manufacturers Deliver Exceptional ProductsIntroduction:In today's fast-paced world, plastic injection molding plays a pivotal role in manufacturing a wide range of products across various industries. As demand continues to surge, the importance of high-quality plastic injection molds cannot be overstated. In this context, {Plastic Injection Mold Manufacturer} emerges as a leading player, leading the industry in delivering cutting-edge solutions for businesses worldwide.Company Overview:{Plastic Injection Mold Manufacturer} is a renowned name in the plastic injection molding industry. With years of industry experience, the company has established its reputation for delivering exceptional products that meet and exceed customer expectations.Using state-of-the-art technology and employing a team of highly skilled professionals, {Plastic Injection Mold Manufacturer} has quickly become a trusted source for precision molds. The company's commitment to quality, reliability, and customer satisfaction has propelled its growth and cemented its position as a market leader.Industry-Leading Solutions: With a primary focus on precision and efficiency, {Plastic Injection Mold Manufacturer} offers a comprehensive range of services to meet various customer requirements. The company's product portfolio includes:1. High-Quality Injection Molds:{Plastic Injection Mold Manufacturer} has a wide assortment of injection molds that cater to diverse industries, such as automotive, electronics, medical, and consumer goods. These molds are designed with utmost precision, ensuring flawless and consistent performance during the manufacturing process.2. Customization Capabilities:Recognizing that every client has unique needs, {Plastic Injection Mold Manufacturer} offers comprehensive customization options for its injection molds. Their team of expert engineers collaborates closely with clients, incorporating specific design features and functionalities into the molds, resulting in tailored solutions that maximize productivity and efficiency.3. Rapid Prototyping:In today's competitive industry landscape, speed is crucial. {Plastic Injection Mold Manufacturer} understands this and offers rapid prototyping services, enabling clients to bring their ideas to life quickly. This allows businesses to test and refine their products before full-scale production, saving time and costs.4. Tooling and Maintenance:To ensure longevity and consistent performance, {Plastic Injection Mold Manufacturer} provides comprehensive tooling and maintenance services. Their skilled technicians perform regular check-ups, repairs, and maintenance to extend the lifespan of injection molds, minimizing downtime and optimizing operational efficiency.Commitment to Quality:{Plastic Injection Mold Manufacturer} takes pride in its commitment to producing high-quality products. They adhere to stringent quality control measures throughout the manufacturing process, ensuring that each mold meets stringent industry standards. By employing advanced machines and employing skilled professionals while adhering to ISO-certified practices, the company maintains its excellence in delivering top-notch injection molds.Environmental Responsibility:In today's environmentally conscious world, manufacturers need to minimize their impact on the environment. {Plastic Injection Mold Manufacturer} recognizes this need and has incorporated sustainable practices into its operations. They utilize eco-friendly materials and processes that reduce waste generation and promote energy efficiency. By doing so, {Plastic Injection Mold Manufacturer} aligns its growth with environmental sustainability.Conclusion:With its unwavering commitment to precision, efficiency, and environmental responsibility, {Plastic Injection Mold Manufacturer} continues to stand out as a trusted and reliable partner for businesses seeking high-quality plastic injection molds. Through their extensive range of services and customization options, the company ensures that clients receive tailor-made solutions that optimize productivity and improve manufacturing processes. As the industry continues to evolve, {Plastic Injection Mold Manufacturer} remains dedicated to delivering exceptional products that exceed customer expectations and drive success in the competitive market.

Discover the Latest High Precision Plastic Injection Molding Parts

[Company Name] Empowers Industries with High Precision Plastic Injection Molding Parts[date][City, State] - [Company Name], a leading provider of high precision plastic injection molding parts, is revolutionizing the manufacturing sector with its cutting-edge technology and expertise. With a focus on delivering impeccable quality and unmatched precision, [Company Name] is poised to empower industries with its innovative solutions.Plastic injection molding is a widely used manufacturing process that has transformed various industries by creating complex and intricate parts with high accuracy and efficiency. The process involves injecting molten plastic into a mold cavity, which then solidifies to form the desired component. [Company Name] has mastered this technique, guaranteeing precise and consistent results every time.The secret to [Company Name]'s success lies in its state-of-the-art manufacturing facility, equipped with the latest machinery and technology. The company utilizes advanced computer-aided design (CAD) software and computer numerical control (CNC) machines for producing molds with exceptional precision. This allows [Company Name] to create intricate parts that meet even the most demanding specifications.Furthermore, [Company Name] takes great pride in its team of highly skilled technicians and engineers. They possess a deep understanding of plastic injection molding and are committed to delivering superior quality products. With their expertise, [Company Name] consistently produces high-grade plastic parts that meet or exceed industry standards.As a leader in the plastic injection molding industry, [Company Name] caters to a wide range of sectors, including automotive, electronics, medical, and consumer goods. The company's extensive product portfolio includes components such as housings, connectors, gears, and various other complex parts. These parts are used in critical applications where precision and durability are paramount.In addition to its dedication to precision and quality, [Company Name] also places a strong emphasis on sustainability. The company recognizes the importance of minimizing its environmental impact and actively seeks ways to reduce waste and energy consumption. By adopting eco-friendly practices, such as recycling and using bio-based materials, [Company Name] aims to contribute to a greener and more sustainable future.To ensure the highest level of customer satisfaction, [Company Name] provides comprehensive support throughout the entire manufacturing process. From initial design and prototyping to final production, the company works closely with its clients, offering expert advice and guidance. This collaborative approach allows [Company Name] to tailor its solutions according to the specific needs and requirements of each customer.As testament to its dedication to excellence, [Company Name] has earned numerous certifications and accolades, including ISO 9001 and ISO 14001. These certifications validate the company's commitment to quality management and environmental stewardship, further instilling confidence in its customers.With its relentless pursuit of perfection, [Company Name] is poised to make a significant impact on the manufacturing sector. By offering high precision plastic injection molding parts and embracing sustainable practices, the company is driving innovation and transforming industries. Whether it's enhancing automotive performance, improving medical devices, or enabling cutting-edge electronics, [company name] is revolutionizing the way industries operate.In conclusion, [Company Name] is revolutionizing the manufacturing sector with its high precision plastic injection molding parts. Through advanced technology, a skilled workforce, and a commitment to sustainability, the company is empowering industries and driving innovation. With its unwavering dedication to excellence, [Company Name] is set to continue its growth and make a lasting impact on the global manufacturing landscape.

Increase in Demand for Sustainable Plastic Products Indicates Growing Environmental Awareness

[Insert Date]Plastic Manufacturer Revolutionizes the Industry with Sustainable Solutions[Location] - In a bid to promote sustainability and combat plastic pollution, Plastic Manufacturer, an industry-leading company, has made substantial strides in revolutionizing the plastic manufacturing industry. By integrating innovative practices and adopting eco-friendly initiatives, Plastic Manufacturer has solidified its commitment to producing sustainable and ethically responsible plastic products.Plastic pollution has become a global crisis, with millions of tons of plastic waste finding its way into our oceans and landfills each year. Recognizing the urgent need for change, Plastic Manufacturer has taken a proactive approach to address this issue. This has cemented the company's position as an industry pioneer and a key player in the transition towards sustainable manufacturing practices.At the heart of Plastic Manufacturer's operations lies a deep-rooted commitment to adopting sustainable solutions. With state-of-the-art manufacturing facilities equipped with cutting-edge technology, the company has embraced eco-friendly alternatives to traditional plastic production methods. By incorporating biodegradable and recyclable materials into their manufacturing process, Plastic Manufacturer is actively reducing the environmental impact associated with plastic production.Additionally, Plastic Manufacturer has initiated strategic partnerships with research institutions and environmental organizations to develop innovative solutions. By collaborating with experts in the field, the company aims to create a positive impact and pave the way for a future where sustainability and profitability coexist harmoniously.One of the landmark achievements of Plastic Manufacturer is the introduction of a revolutionary bio-based plastic. Utilizing plant-based materials, this plastic variant offers the same performance characteristics as traditional plastic while being completely biodegradable. This breakthrough has the potential to significantly reduce the environmental impact of plastic waste and create a more sustainable future for generations to come.To ensure the traceability and transparency of its processes, Plastic Manufacturer has implemented an advanced tracking system that allows customers to access detailed information about the origin and composition of their plastic products. This commitment to transparency not only builds trust with customers but also helps raise awareness about the importance of responsible plastic consumption.Furthermore, Plastic Manufacturer places a strong emphasis on recycling and waste management. Through the establishment of recycling initiatives, the company actively promotes the recycling of plastic waste, minimizing its contribution to landfill sites. By encouraging the use of recycled plastic materials, Plastic Manufacturer aims to create a circular economy where plastic waste is repurposed and given new life, instead of ending up as pollution.To drive further change, Plastic Manufacturer actively engages with local communities, government agencies, and non-profit organizations in educational campaigns and initiatives. By emphasizing the importance of individual responsibility in plastic consumption and disposal, the company seeks to create a widespread culture of sustainability.In recognition of its remarkable efforts, Plastic Manufacturer has received several accolades and certifications for its commitment to sustainable practices. Notably, the company has been awarded the Sustainable Manufacturing Excellence Award, signifying its contribution to reducing environmental harm and promoting sustainable development.Looking forward, Plastic Manufacturer envisions a future where sustainability is ingrained within the fabric of the plastic manufacturing industry. The company's unwavering commitment to sustainable solutions, continual research and development, and collaborative partnerships have positioned it as a leader, inspiring other manufacturers to follow suit.Plastic Manufacturer's revolutionary approach not only addresses the environmental challenges posed by plastic pollution but also serves as a testament to the immense possibilities that arise when businesses prioritize sustainability. By aspiring to create a better world, Plastic Manufacturer sets a precedent for other companies to incorporate sustainable practices into their operations, ultimately leading to a greener and healthier planet for future generations.In conclusion, Plastic Manufacturer's dedication to sustainable manufacturing solutions shines a light on the path towards a more sustainable future. Through innovative practices, partnerships, and a strong commitment to transparency, the company is pioneering the transformation of the plastic manufacturing industry. By actively promoting recycling, creating bio-based plastics, and engaging in educational initiatives, Plastic Manufacturer continues to drive change and inspire others to embrace sustainability.

Unlocking the Power of Servo Motors in Injection Moulding Plastics

Title: Revolutionary Servo Motor Technology in Injection Moulding PlasticsIntroduction:In the ever-evolving world of manufacturing, companies are continuously seeking technological advancements to enhance production efficiency and improve product quality. One such breakthrough in the field of injection moulding plastics is the advent of Servo Motor Technology. This revolutionary innovation eliminates the limitations of conventional hydraulic systems and paves the way for more precise and energy-efficient manufacturing processes. This article delves into the transformative impact of Servo Motor Technology on injection moulding plastics and its potential to revolutionize the industry.I. Background:Injection moulding plastics, a widely adopted manufacturing process, involves the creation of plastic products through the injection of molten material into a mould. Traditionally, hydraulic systems powered by pumps were used to drive the injection process, resulting in limitations such as excess energy consumption, imprecise control, and inconsistent product quality. These shortcomings paved the way for the emergence of an alternative: Servo Motor Technology.II. Servo Motor Technology Explained:Servo motors, unlike hydraulic systems, utilize electrical power to drive the injection process. This cutting-edge technology offers superior control, precision, and efficiency. The servo motor system consists of a motor, an encoder, a controller, and a hydraulic accumulator. The encoder provides real-time data on the position and velocity of the motor, enabling the controller to regulate the injection process accurately. This ensures precise and repeatable positioning of the mould, resulting in uniform product quality.III. Advantages of Servo Motor Technology:1. Energy Efficiency: Servo motors consume considerably less energy compared to traditional hydraulic systems. By closely matching the speed and torque requirements of the injection process, the servo motor system reduces wasteful energy consumption, leading to substantial cost savings for manufacturers.2. Improved Precision and Control: Servo Motor Technology enables precise control over the injection process, offering greater accuracy in terms of shot weight, injection timing, and mould positioning. This not only enhances the overall quality of products but also reduces material waste and rework, making it an environmentally friendly solution.3. Reduced Noise Levels: Servo motors operate more quietly and smoothly as compared to hydraulic systems. This reduction in noise pollution contributes to a safer and more pleasant working environment for operators.IV. Application and Impact:The implementation of Servo Motor Technology drives advancements across various industries that rely on injection moulding plastics. Automotive, consumer goods, electronics, and packaging sectors are among the key beneficiaries of this transformative technology. Automakers benefit from accurate and consistent production of automotive parts, while the consumer goods industry enjoys improved product reliability and efficiency. Electronics manufacturers can achieve precise positioning of complex moulds, leading to enhanced product performance. Furthermore, the packaging industry benefits from increased productivity and minimized material waste.V. Market Outlook:The global injection moulding plastics market is projected to witness substantial growth owing to various factors, including the introduction of innovative technologies like Servo Motor Technology. Manufacturers are showing increased interest in adopting this technology to gain a competitive edge. Furthermore, the rising environmental concerns and stringent regulations related to energy consumption and carbon emissions are expected to propel the demand for energy-efficient solutions such as Servo Motor Technology.Conclusion:As the manufacturing industry seeks to optimize productivity and enhance product quality while minimizing energy consumption, Servo Motor Technology provides an effective solution for injection moulding plastics. The advantages of this groundbreaking technology, including improved precision, energy efficiency, and reduced noise levels, are poised to revolutionize the industry. With its widespread application across various sectors, Servo Motor Technology is set to usher in a new era of efficiency and sustainability in the injection moulding plastics market.