- Home

- Blog

- Unlocking the Power of Injection Over Molding: A Revolutionary Technique Reshaping the Industry

Unlocking the Power of Injection Over Molding: A Revolutionary Technique Reshaping the Industry

By:Admin

Introduction:

In today's highly competitive manufacturing industry, companies are constantly seeking innovative solutions to advance their production processes. One such breakthrough is Injection Over Molding, a cutting-edge technique that combines polymers and other materials to enhance product functionality, durability, and aesthetics. Leading the charge in this realm is an industry pioneer, whose commitment to technological advancements has revolutionized the manufacturing landscape.

Company Overview:

With a rich history spanning several decades, [Company Name] has emerged as a global leader in the manufacturing sector. The company's core ethos revolves around driving innovation and pushing boundaries to deliver state-of-the-art solutions to clients spanning various industries. With a highly skilled team of engineers and technicians, coupled with world-class facilities, [Company Name] has successfully established a track record of excellence, setting new benchmarks in manufacturing.

1. Introduction to Injection Over Molding:

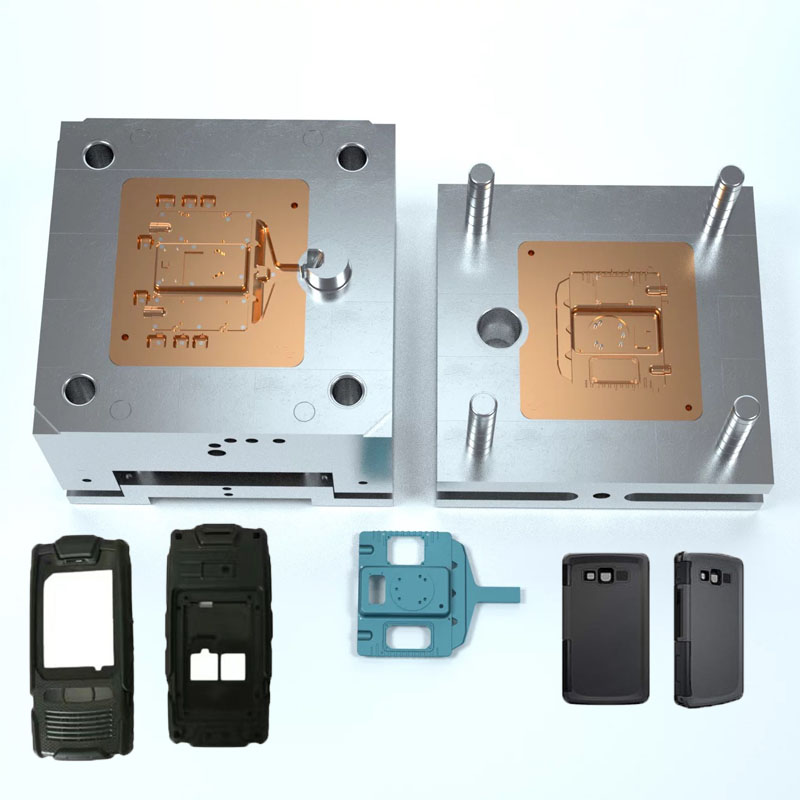

Injection Over Molding is a groundbreaking technique that combines injection molding with over molding to create complex products with enhanced functionality. It involves injecting molten materials into a mold, effectively encapsulating a pre-formed component or substrate. The result is a seamless integration of multiple materials, providing superior product performance and aesthetic appeal.

2. Advantages of Injection Over Molding:

a. Enhanced Functionality: The ability to encapsulate multiple materials within a single mold enables the production of products with improved functionality and performance. Injection Over Molding allows for the integration of various materials such as rubber, metal, or electronics into a single component, leading to increased durability and versatility.

b. Design Flexibility: With Injection Over Molding, manufacturers can achieve complex designs that would otherwise be difficult or costly to produce. This versatility allows companies to create products that meet specific requirements while maintaining a sleek and ergonomic design.

c. Cost Savings: By combining multiple materials into a single mold, manufacturers can reduce production costs associated with assembling multiple components. Additionally, the seamless integration of materials eliminates the need for additional assembly steps, streamlining the production process and decreasing overall manufacturing time.

3. Applications of Injection Over Molding:

a. Automotive Industry: Injection Over Molding is widely employed in the automotive sector to produce components such as instrument panels, door handles, buttons, and switches. The technique's ability to combine different materials enables manufacturers to create durable and visually appealing parts that enhance the overall driving experience.

b. Electronics Industry: The electronics industry extensively utilizes Injection Over Molding for producing casings, connectors, and keypads. The technique ensures enhanced durability against external elements, such as moisture and shock, while maintaining optimal functionality.

c. Medical Industry: Injection Over Molding finds applications in the medical field for creating devices such as syringe bodies, ergonomic grips, and electrodes. The seamless integration of materials ensures a safe and hygienic product, while its design flexibility aids in the creation of ergonomic and user-friendly medical equipment.

4. The Role of [Company Name] in Advancing Injection Over Molding:

As a pioneer in Injection Over Molding, [Company Name] has played a pivotal role in advancing this groundbreaking technique. By harnessing state-of-the-art technology and leveraging their extensive expertise, the company has consistently pushed the boundaries of what is possible in the manufacturing industry.

[Company Name]'s commitment to innovation and customer satisfaction has positioned them at the forefront of the industry. Their cutting-edge facilities, research labs, and highly skilled team of engineers enable them to deliver bespoke solutions to clients across various sectors, revolutionizing the way products are manufactured.

Conclusion:

Injection Over Molding represents an exciting leap forward in manufacturing technology. With its ability to combine multiple materials seamlessly, this technique enhances functionality, design flexibility, and cost-effectiveness, making it highly attractive to industries across the board. Spearheading this revolution, [Company Name] continues to lead the way by delivering groundbreaking solutions that redefine the manufacturing industry's standards.

Company News & Blog

Enhance Your Furniture with Stylish Plastic Injection Mold Decorative Handles

Plastic Injection Mould Decorative Furniture Handle Revolutionizes Interior Design[City, Date] – In the ever-evolving world of interior design, innovation and creativity are crucial. One company leading the way in bringing cutting-edge solutions to the market is [Company Name]. With their latest creation, the Plastic Injection Mould Decorative Furniture Handle, they are revolutionizing how furniture is accessorized and transforming the aesthetics of living spaces.[Company Name] has earned a reputation for pushing the boundaries of design and craftsmanship. Their commitment to quality and attention to detail has made them a leader in the industry. The new Plastic Injection Mould Decorative Furniture Handle is a testament to their dedication to excellence.This groundbreaking handle is not just a functional component of furniture; it is an artistic masterpiece that elevates the overall look of any piece it adorns. Made from high-quality plastic through an advanced injection molding process, the handle is not only durable but also customizable to fit the unique style of each customer.One of the key advantages of the Plastic Injection Mould Decorative Furniture Handle is its wide range of design options. The handle comes in a variety of shapes, sizes, and finishes, enabling customers to select the perfect match for their furniture style. Whether it's a sleek and modern look or a more traditional and ornate design, there is a handle for every taste.Moreover, the injection molding process ensures that each handle is produced with precision and consistency, guaranteeing uniform quality across multiple pieces. This ensures that the handles maintain their form and functionality, no matter how frequently they are used.Not only are these handles visually appealing, but they are also ergonomically designed to provide optimal comfort and ease of use. Their enhanced grip and smooth finish make opening drawers and doors effortless, adding convenience to the overall furniture experience.The Plastic Injection Mould Decorative Furniture Handle is not confined to specific types of furniture. It is versatile and can be seamlessly integrated into various pieces, including cabinets, wardrobes, dressers, and even kitchen cabinets. This versatility expands the possibilities of incorporating these handles into different interior design styles and applications.Furthermore, the environmental impact of these handles is significantly reduced compared to traditional manufacturing methods. The injection molding process minimizes material waste and allows for recycling, making them an eco-friendly choice for conscious customers.[Company Name], with its deep understanding of the market demands, ensures that the Plastic Injection Mould Decorative Furniture Handle is not only of superior quality but also reasonably priced. This accessibility allows a wider range of customers to experience the transformative effects of these handles on their furniture pieces.As the demand for unique and personalized furniture accessories continues to grow, [Company Name] remains at the forefront of providing innovative solutions. With the introduction of the Plastic Injection Mould Decorative Furniture Handle, they have once again proven themselves as pioneers in the industry, setting new standards for design, functionality, and aesthetics.In conclusion, the Plastic Injection Mould Decorative Furniture Handle manufactured by [Company Name] is a game-changer in the world of interior design. Its artistic designs, customizable options, and durability make it the perfect addition to any furniture piece. With this remarkable creation, [Company Name] continues to inspire creativity and redefine the way we perceive furniture handles.

Discover the Latest High Precision Plastic Injection Molding Parts

[Company Name] Empowers Industries with High Precision Plastic Injection Molding Parts[date][City, State] - [Company Name], a leading provider of high precision plastic injection molding parts, is revolutionizing the manufacturing sector with its cutting-edge technology and expertise. With a focus on delivering impeccable quality and unmatched precision, [Company Name] is poised to empower industries with its innovative solutions.Plastic injection molding is a widely used manufacturing process that has transformed various industries by creating complex and intricate parts with high accuracy and efficiency. The process involves injecting molten plastic into a mold cavity, which then solidifies to form the desired component. [Company Name] has mastered this technique, guaranteeing precise and consistent results every time.The secret to [Company Name]'s success lies in its state-of-the-art manufacturing facility, equipped with the latest machinery and technology. The company utilizes advanced computer-aided design (CAD) software and computer numerical control (CNC) machines for producing molds with exceptional precision. This allows [Company Name] to create intricate parts that meet even the most demanding specifications.Furthermore, [Company Name] takes great pride in its team of highly skilled technicians and engineers. They possess a deep understanding of plastic injection molding and are committed to delivering superior quality products. With their expertise, [Company Name] consistently produces high-grade plastic parts that meet or exceed industry standards.As a leader in the plastic injection molding industry, [Company Name] caters to a wide range of sectors, including automotive, electronics, medical, and consumer goods. The company's extensive product portfolio includes components such as housings, connectors, gears, and various other complex parts. These parts are used in critical applications where precision and durability are paramount.In addition to its dedication to precision and quality, [Company Name] also places a strong emphasis on sustainability. The company recognizes the importance of minimizing its environmental impact and actively seeks ways to reduce waste and energy consumption. By adopting eco-friendly practices, such as recycling and using bio-based materials, [Company Name] aims to contribute to a greener and more sustainable future.To ensure the highest level of customer satisfaction, [Company Name] provides comprehensive support throughout the entire manufacturing process. From initial design and prototyping to final production, the company works closely with its clients, offering expert advice and guidance. This collaborative approach allows [Company Name] to tailor its solutions according to the specific needs and requirements of each customer.As testament to its dedication to excellence, [Company Name] has earned numerous certifications and accolades, including ISO 9001 and ISO 14001. These certifications validate the company's commitment to quality management and environmental stewardship, further instilling confidence in its customers.With its relentless pursuit of perfection, [Company Name] is poised to make a significant impact on the manufacturing sector. By offering high precision plastic injection molding parts and embracing sustainable practices, the company is driving innovation and transforming industries. Whether it's enhancing automotive performance, improving medical devices, or enabling cutting-edge electronics, [company name] is revolutionizing the way industries operate.In conclusion, [Company Name] is revolutionizing the manufacturing sector with its high precision plastic injection molding parts. Through advanced technology, a skilled workforce, and a commitment to sustainability, the company is empowering industries and driving innovation. With its unwavering dedication to excellence, [Company Name] is set to continue its growth and make a lasting impact on the global manufacturing landscape.

Custom Plastic Injection Molding Service Offers Top-notch Mould Solutions

Title: Industry-Leading Plastic Injection Molding Service Revolutionizes Manufacturing ProcessesIntroduction:In an era of constant innovation and technological advancements, one company has emerged as a frontrunner in the field of custom plastic injection molding services. Located in [Company's Location], this industry-leading firm has been offering a wide range of cutting-edge solutions to meet the diverse manufacturing needs of clients across various industries. With its state-of-the-art facilities, highly skilled workforce, and unwavering commitment to quality, the company has established itself as a go-to partner for businesses seeking reliable and efficient plastic injection molding services.Body:1. Overview of the Company:[Company Name], a prominent player in the plastic injection molding industry, has been providing exceptional solutions and value-added services since its establishment. Founded with a vision to revolutionize the manufacturing landscape, the company has continuously invested in infrastructure and equipped its facilities with the latest technology to stay ahead of the competition. With a strong focus on quality, precision, and customer satisfaction, [Company Name] has become synonymous with excellence in plastic injection molding.2. Extensive Range of Services:At [Company Name], they understand that every client's project is unique. Therefore, they offer a diverse range of services to cater to various manufacturing requirements. From prototype development to large-scale production runs, their capabilities cover a wide spectrum of industries, including automotive, electronics, medical, consumer goods, and more. Whether it is manufacturing intricate components or producing complete assembly parts, the company delivers efficient and cost-effective solutions tailored to the specific needs of each client.3. Cutting-Edge Technology and Facilities:One of the key factors behind the success of [Company Name] is its continuous investment in advanced technology. The company utilizes state-of-the-art plastic injection molding machines and tools to ensure accuracy, consistency, and superior quality in all produced parts. Moreover, their facilities strictly adhere to international standards, enabling them to maintain exceptional levels of cleanliness, hygiene, and safety. The company's commitment to maintaining a technologically advanced infrastructure is a testament to their dedication to providing exemplary services.4. Expertise and Skilled Workforce:The skilled workforce at [Company Name] combines years of experience with extensive knowledge of plastic injection molding techniques. From design and engineering to production and quality control, their experts work collaboratively with clients to optimize designs, enhance manufacturability, and achieve desired outcomes. The team's proficiency in working with different materials, such as ABS, PC, PP, and more, allows them to produce components that meet the highest industry standards with precision and consistency.5. Strict Quality Control Measures:Emphasizing quality as a paramount focus, all manufacturing processes at [Company Name] are subjected to rigorous quality control measures. The company adheres to internationally recognized quality management systems, such as ISO 9001, to ensure that the final products exceed customer expectations. From material selection to mold design and from injection molding to final inspection, each step undergoes thorough checks and balances to guarantee the delivery of defect-free parts.6. Commitment to Sustainability:In an era marked by increased environmental awareness, [Company Name] recognizes the importance of sustainable practices. The company takes pride in its efficient use of resources, recycling programs, and waste reduction strategies. By employing eco-friendly materials and optimizing production processes, they minimize the impact on the environment while ensuring the highest quality of their products. This commitment to sustainable manufacturing makes [Company Name] a responsible and socially conscious player in the industry.Conclusion:[Company Name]'s custom plastic injection molding services have democratized manufacturing processes, enabling businesses of all sizes to benefit from cost-effective solutions and superior product quality. By leveraging cutting-edge technology, maintaining stringent quality control measures, and fostering a team of skilled experts, the company has set a benchmark for the industry. With unparalleled expertise and a commitment to customer satisfaction, [Company Name] is poised to shape the future of plastic injection molding, propelling the manufacturing sector into an era of unprecedented possibilities.

Discover the Incredible Value of Smoothie Juicer Blenders and Food Blenders in China

Title: Chinese Smoothie Juicers and Blenders Reshape the MarketIntroduction:China's smoothie juicer blender and food blender market is witnessing a significant surge in demand as consumers increasingly embrace healthier lifestyles. These high-performance appliances are bridging the gap between convenience and wellness by offering versatile options for creating nutritious drinks and meals at home. Let's explore the current trends and key players in this booming industry.Rising Popularity:In recent years, there has been a remarkable shift in consumer preferences towards healthier food choices, leading to an upsurge in the demand for smoothies and blended recipes. This shift can be attributed to heightened awareness of the importance of a balanced diet and the desire to maintain a healthy lifestyle. Chinese smoothie juicer blender and food blender manufacturers have stepped up to cater to this growing demand, providing consumers with innovative options for creating delicious and nutrient-rich concoctions.Tech-Driven Features:One of the key reasons behind the success of Chinese smoothie juicer blender and food blender brands is their focus on advanced technology. These blenders feature powerful motors that crush through dense ingredients, ensuring a smooth consistency. Additionally, many models incorporate smart features such as preset programs, touch control panels, and even Bluetooth connectivity, making the blending experience more convenient and intuitive.Competitive Pricing:Chinese brands have gained a competitive edge in the global market due to their affordability. These smoothie juicer blender and food blender offerings combine quality with cost-effectiveness, making them accessible to a wider range of consumers. By avoiding excessive price tags, Chinese manufacturers have managed to capture both domestic and international markets, challenging established global brands.Efficiency and Durability:With a strong emphasis on quality and durability, Chinese smoothie juicer blender and food blender manufacturers have garnered trust and loyalty from customers. These appliances are designed to withstand intense usage, boasting robust materials and efficient engineering. Their long-lasting performance translates into a wise investment for consumers, offering both reliability and value for money.Market Leaders:As the market expands, several notable Chinese brands have emerged as key players, setting new standards in terms of functionality and design. These industry leaders offer a comprehensive range of smoothie juicer blenders and food blenders, catering to varying needs and preferences.One such prominent brand is X Company, known for its cutting-edge innovations in the blending industry. Their wide product range caters to beginners and professionals alike, with options designed specifically for smoothies, soups, or even baby food. X Company leverages advanced technology to deliver superior blending performance, making them a top choice among consumers.Another noteworthy brand is Y Company, renowned for its commitment to health and wellness. Y Company's blenders are equipped with unique features like personal blending cups and precise nutrient extraction modes, enabling users to tailor their blend according to specific dietary requirements. The brand's dedication to promoting healthy lifestyles has been well-received by health-conscious consumers.Conclusion:Chinese smoothie juicer blender and food blender brands have revolutionized the market, offering consumers an extensive range of affordable and feature-packed options. With a focus on technology, efficiency, and durability, these appliances have become an indispensable tool for individuals seeking to lead a healthier lifestyle. As the market continues to evolve, it is expected that Chinese brands will continue to innovate and cater to the ever-growing demand for high-quality and versatile blending solutions.

Discover the Leading ABS Plastic Injection China Mould Manufacturer

Title: Leading Manufacturer of ABS Plastic Injection Molds in China Sets New Industry StandardsIntroduction: In the ever-growing global market, the demand for high-quality plastic products is constantly on the rise. One of the key factors contributing to this increasing demand is the versatility and durability of ABS plastic. It is widely used in various industries, including automotive, electronics, and consumer goods. Recognizing this demand, a renowned Chinese manufacturer specializing in ABS plastic injection molds has emerged as a dominant force in the industry. With their cutting-edge technology, state-of-the-art facilities, and commitment to innovation, they have set new standards for excellence in the production of injection molds.Body:1. Company Background and Development:Established in the heart of China's manufacturing hub, this leading ABS plastic injection mold manufacturer has decades of experience in the industry. Their commitment to delivering high-quality products and exceptional customer service has helped them gain a strong reputation both in China and internationally. The company has consistently invested in research and development to improve their manufacturing processes and stay ahead of the competition.2. Technological Advancements:This manufacturer stands out from the competition due to its focus on technological advancements. Their state-of-the-art facilities are equipped with the latest machinery and tools, enabling them to produce injection molds of diverse sizes and complexities. By employing computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, the company ensures precision and accuracy in every mold they produce. This dedication to technology-driven manufacturing sets them apart from traditional mold manufacturers.3. Excellent Quality Control:Quality control is a top priority for this manufacturer. They adhere to stringent standards and maintain a comprehensive quality management system throughout the production process. This includes careful material selection, rigorous testing, and continuous monitoring to ensure the molds meet or exceed customer expectations. By employing a team of experienced engineers and technicians, they conduct thorough inspections at every stage of production, guaranteeing the highest level of quality and reliability.4. Versatile Application and Customization:The versatility of ABS plastic injection molds allows them to be used across a wide range of industries. From automotive parts to consumer electronics and household appliances, this manufacturer has the expertise to develop molds that meet the unique specifications of each customer. Their team of skilled professionals collaborates closely with clients to understand their specific requirements. With this collaborative approach, they offer cost-effective solutions tailored to the client's needs, ensuring optimum performance and efficiency.5. Commitment to Environmental Responsibility:This leading Chinese manufacturer also places great emphasis on environmental responsibility. They actively adopt sustainable practices during the manufacturing process, including the use of eco-friendly materials and recycling waste products. By making conscious efforts to minimize their environmental impact, they contribute to a greener future and uphold their social responsibilities as a manufacturer.6. Expansion and International Reach:Despite being based in China, the manufacturer has achieved a global presence and serves customers from around the world. Their commitment to high-quality products, timely delivery, and competitive pricing has garnered them a loyal customer base. They continue to expand their operations, establishing strong partnerships with international companies and distributors. Through their exceptional customer support and dedication to customer satisfaction, this manufacturer has gained recognition and respect on both the domestic and international stages.Conclusion:With an unwavering commitment to technological innovation, exceptional product quality, and sustainable manufacturing practices, this Chinese ABS plastic injection mold manufacturer has become the industry benchmark. Their ability to customize molds for a range of applications, combined with their expansive international reach, positions them as a leader in the global market. As the demand for ABS plastic products continues to grow, this manufacturer's dedication to excellence and customer-centric approach ensures they will retain their position at the forefront of the industry.

Exploring the Growing Demand for Plastic Medical Injection Moulds

Title: Revolutionary Plastic Medical Injection Mould Pioneers Breakthrough Technologies in HealthcareIntroduction:(Date) - As the demand for efficient and safe medical equipment continues to rise, a renowned plastic injection mould company has unveiled its groundbreaking Plastic Medical Injection Mould. Developed in partnership with industry leaders and guided by advanced technologies, this innovative solution promises to revolutionize the production of medical equipment while ensuring optimal patient care and safety.Company Background:Founded in (year), (Company Name) has consistently been at the forefront of providing cutting-edge plastic injection mould solutions across various industries. Fueled by a commitment to innovation and customer satisfaction, the company has established a reputation for delivering superior products that meet the evolving needs of clients worldwide. With an uncompromising focus on quality and efficiency, (Company Name) has now set its sights on transforming the medical field.The Plastic Medical Injection Mould:The newly unveiled Plastic Medical Injection Mould showcases the culmination of years of research and development by (Company Name)'s team of experts. This revolutionary mould is designed to facilitate the production of high-quality and precise medical equipment, including syringes, IV catheters, infusion sets, and other vital medical components.Key Features and Benefits:1. Enhanced Precision and Accuracy: The Plastic Medical Injection Mould ensures the production of medical equipment with unparalleled precision and accuracy. With strict adherence to meticulous design specifications, it minimizes errors and discrepancies, guaranteeing the safety and effectiveness of the final product.2. Exceptional Material Compatibility: (Company Name)'s mould integrates advanced material compatibility features, allowing for seamless production with a wide range of medical-grade plastics. The mould is engineered to maintain the integrity of the materials used, ensuring the highest standards of quality and durability.3. Streamlined Production Process: Leveraging state-of-the-art automation technology, the Plastic Medical Injection Mould optimizes the production process, reducing cycle times and increasing output. This enables manufacturers to meet the growing demands of the healthcare industry while minimizing labor costs and maximizing efficiency.4. Strict Adherence to Regulatory Standards: Understanding the critical importance of regulatory compliance in the medical field, (Company Name) has rigorously tested the Plastic Medical Injection Mould to ensure adherence to global quality and safety standards. Manufacturers can be confident that their products will meet all necessary certifications and regulatory requirements.Impact on Healthcare:The launch of the Plastic Medical Injection Mould signifies a significant breakthrough in the healthcare industry. By enabling the production of premium medical equipment, healthcare providers can enhance the quality of patient care, reduce the risk of contamination, and streamline critical processes. The mould's reliable performance and compatibility with a range of plastics allow for cost-effective and sustainable manufacturing practices, making high-quality medical equipment more accessible to healthcare organizations worldwide.Future Prospects:Moving forward, (Company Name) is committed to continually pushing the boundaries of plastic injection mould technology to meet the evolving needs of the healthcare sector. By collaborating with medical professionals and industry stakeholders, the company aims to develop customized moulds that cater to specific medical equipment requirements, further improving patient outcomes and ensuring the highest levels of safety.Conclusion:With the introduction of the Plastic Medical Injection Mould, (Company Name) has established itself as a pioneer in developing innovative solutions for the healthcare industry. This groundbreaking mould's advanced features and benefits have the potential to revolutionize the way medical equipment is produced, enhancing patient care, and driving forward the progress of the healthcare sector as a whole.

Unlocking the Power of Injection Over Molding: A Revolutionary Technique Reshaping the Industry

Title: Innovative Injection Over Molding Revolutionizes Manufacturing ProcessesIntroduction:In today's highly competitive manufacturing industry, companies are constantly seeking innovative solutions to advance their production processes. One such breakthrough is Injection Over Molding, a cutting-edge technique that combines polymers and other materials to enhance product functionality, durability, and aesthetics. Leading the charge in this realm is an industry pioneer, whose commitment to technological advancements has revolutionized the manufacturing landscape.Company Overview:With a rich history spanning several decades, [Company Name] has emerged as a global leader in the manufacturing sector. The company's core ethos revolves around driving innovation and pushing boundaries to deliver state-of-the-art solutions to clients spanning various industries. With a highly skilled team of engineers and technicians, coupled with world-class facilities, [Company Name] has successfully established a track record of excellence, setting new benchmarks in manufacturing.1. Introduction to Injection Over Molding:Injection Over Molding is a groundbreaking technique that combines injection molding with over molding to create complex products with enhanced functionality. It involves injecting molten materials into a mold, effectively encapsulating a pre-formed component or substrate. The result is a seamless integration of multiple materials, providing superior product performance and aesthetic appeal.2. Advantages of Injection Over Molding:a. Enhanced Functionality: The ability to encapsulate multiple materials within a single mold enables the production of products with improved functionality and performance. Injection Over Molding allows for the integration of various materials such as rubber, metal, or electronics into a single component, leading to increased durability and versatility.b. Design Flexibility: With Injection Over Molding, manufacturers can achieve complex designs that would otherwise be difficult or costly to produce. This versatility allows companies to create products that meet specific requirements while maintaining a sleek and ergonomic design.c. Cost Savings: By combining multiple materials into a single mold, manufacturers can reduce production costs associated with assembling multiple components. Additionally, the seamless integration of materials eliminates the need for additional assembly steps, streamlining the production process and decreasing overall manufacturing time.3. Applications of Injection Over Molding:a. Automotive Industry: Injection Over Molding is widely employed in the automotive sector to produce components such as instrument panels, door handles, buttons, and switches. The technique's ability to combine different materials enables manufacturers to create durable and visually appealing parts that enhance the overall driving experience.b. Electronics Industry: The electronics industry extensively utilizes Injection Over Molding for producing casings, connectors, and keypads. The technique ensures enhanced durability against external elements, such as moisture and shock, while maintaining optimal functionality.c. Medical Industry: Injection Over Molding finds applications in the medical field for creating devices such as syringe bodies, ergonomic grips, and electrodes. The seamless integration of materials ensures a safe and hygienic product, while its design flexibility aids in the creation of ergonomic and user-friendly medical equipment.4. The Role of [Company Name] in Advancing Injection Over Molding:As a pioneer in Injection Over Molding, [Company Name] has played a pivotal role in advancing this groundbreaking technique. By harnessing state-of-the-art technology and leveraging their extensive expertise, the company has consistently pushed the boundaries of what is possible in the manufacturing industry.[Company Name]'s commitment to innovation and customer satisfaction has positioned them at the forefront of the industry. Their cutting-edge facilities, research labs, and highly skilled team of engineers enable them to deliver bespoke solutions to clients across various sectors, revolutionizing the way products are manufactured.Conclusion:Injection Over Molding represents an exciting leap forward in manufacturing technology. With its ability to combine multiple materials seamlessly, this technique enhances functionality, design flexibility, and cost-effectiveness, making it highly attractive to industries across the board. Spearheading this revolution, [Company Name] continues to lead the way by delivering groundbreaking solutions that redefine the manufacturing industry's standards.

Top Plastic Mold Injection Service for Quality Manufacturing

[Your Company Name] Offers Cutting-Edge Plastic Mold Injection Service, Revolutionizing Manufacturing Processes[City, Date] - [Your Company Name], a leading provider of advanced manufacturing solutions, is at the forefront of the industry with its innovative plastic mold injection service. Through state-of-the-art technology, skilled professionals, and a commitment to delivering exceptional quality, [Your Company Name] is revolutionizing the way plastic products are manufactured.Plastic mold injection has become a fundamental manufacturing method across various industries, enabling the production of complex and intricate components. With [Your Company Name]'s expertise in this sector, clients can enjoy a seamless and efficient manufacturing process with reduced lead times and enhanced product performance."At [Your Company Name], we understand the ever-evolving demands of the manufacturing industry, which is why we continuously invest in cutting-edge technology and highly-skilled professionals. Our plastic mold injection service allows us to offer our clients unparalleled precision, speed, and reliability," says [Company Spokesperson].Guided by a commitment to excellence, [Your Company Name] employs a comprehensive approach to plastic mold injection, beginning with thorough consultation services. By collaborating closely with clients, the company's experts ensure a tailored solution that meets their exact requirements. Through meticulous design analysis and prototyping, potential design flaws and gaps in functionality are identified, allowing for valuable modifications before the manufacturing process begins.State-of-the-art facilities and advanced machinery enable [Your Company Name] to deliver unrivaled manufacturing capabilities. Equipped with a wide range of plastic material options, including ABS, PET, HDPE, PP, and many others, the company's expert engineers ensure that each component is produced to the highest standards. Surface finishes such as texture, gloss, and multi-color options provide further customization possibilities for clients seeking to differentiate their products in the market.A key advantage of [Your Company Name]'s plastic mold injection service is its ability to deliver products in large volumes, while still maintaining exceptional quality control. Through careful monitoring and rigorous inspection processes, any defects or imperfections are identified and rectified promptly, minimizing waste and ensuring optimum productivity.By integrating robotic automation into its manufacturing processes, [Your Company Name] has further enhanced its efficiency and precision. This automation allows for high-speed production, reducing the turnaround time for projects and ensuring on-time delivery for clients.Environmental sustainability is also a primary focus for [Your Company Name]. The company employs eco-friendly practices throughout its manufacturing operations, including responsible waste management, recycling initiatives, and the utilization of energy-efficient machinery. By prioritizing sustainability, [Your Company Name] actively contributes to the preservation of our planet for present and future generations.The extensive expertise and industry knowledge of [Your Company Name]'s team sets them apart from the competition. From the initial consultation to the final delivery of the product, the company's professionals are dedicated to providing unparalleled customer service and support. Their commitment to building long-term relationships, paired with their technical prowess, ensures that clients receive not only high-quality components but also a seamless and enjoyable experience.With its cutting-edge plastic mold injection service, [Your Company Name] is driving innovation in the manufacturing industry. By embracing technology, employing skilled professionals, and prioritizing client satisfaction, the company continues to exceed expectations and redefine the possibilities of plastic product manufacturing.About [Your Company Name] (need remove brand name):[Your Company Name] is a leading provider of advanced manufacturing solutions, specializing in plastic mold injection. With state-of-the-art facilities and a team of highly-skilled professionals, the company delivers exceptional quality, precision, and efficiency for clients across various industries. [Your Company Name]'s commitment to innovation, sustainability, and customer satisfaction has firmly established it as a trusted name in the manufacturing sector.For media inquiries, please contact:[Company Spokesperson][Your Company Name]Phone: [Phone Number]Email: [Email Address]Website: [Website URL]

Exploring the Versatility and Benefits of Mould Injection Plastic for Various Applications

Mould Injection Plastic Used in Various Industries: A Revolution in ManufacturingIn the ever-evolving world of manufacturing, technological advancements continually reshape the way products are created and produced. One such breakthrough that has revolutionized industries across the globe is the use of mould injection plastic. This innovative technique, which involves injecting molten plastic into a pre-designed mould, has numerous applications and advantages that make it highly sought after by manufacturers.Traditionally, manufacturing processes involved creating products through techniques such as casting, machining, or extrusion. While effective, these methods often presented limitations in terms of design flexibility, production speed, and cost-effectiveness. However, the introduction of mould injection plastic has changed the game by addressing these shortcomings and offering a multitude of benefits.One company that has successfully embraced this cutting-edge technique is {}. With years of experience in the industry, they have become a reliable and renowned provider of mould injection plastic solutions. By combining advanced technology with expertise in design and engineering, they deliver top-quality products to a wide range of sectors.The automotive industry, for example, has greatly benefited from the introduction of mould injection plastic. The use of this technique allows car manufacturers to produce complex parts with customized designs at a fraction of the cost compared to traditional methods. From interior components like dashboards and door panels to exterior elements such as bumpers and grilles, mould injection plastic has become an essential part of modern automotive production.Moreover, the medical field has also witnessed significant advancements thanks to mould injection plastic. The ability to manufacture sterile and precise components for medical devices, implants, and diagnostic equipment has greatly improved patient care and treatment outcomes. The use of high-quality, durable polymers in medical applications has led to enhanced safety measures and reduced risks associated with product contamination.Another area where mould injection plastic has found extensive use is consumer electronics. With constant demand for smaller, lighter, and more appealing product designs, manufacturers in this sector rely heavily on this technique. From mobile phone casings to computer keyboards, the ability to produce intricate and visually appealing components in large quantities has propelled the consumer electronics industry forward.Furthermore, the packaging industry has witnessed a significant transformation due to the introduction of mould injection plastic. As consumers increasingly prioritize sustainability and environmental friendliness, manufacturers have turned to this technique to create eco-friendly packaging solutions. By utilizing biodegradable plastics and optimizing the design process, companies can now produce packaging materials that reduce waste and contribute to a greener future.The advantages of mould injection plastic are not limited to these industries alone. Its versatility allows for the production of a wide range of products, such as toys, furniture, sports equipment, and even aerospace components. The ability to create intricate shapes, incorporate multiple materials, and achieve high levels of precision has opened up endless possibilities for manufacturers.Considering the growing demand for mould injection plastic, companies like {} have significantly invested in state-of-the-art equipment and technology. This, coupled with a highly skilled workforce, enables them to cater to the diverse needs and requirements of their clients. From initial product design to the final delivery, they prioritize quality and customer satisfaction, positioning themselves as leaders in the mould injection plastic industry.In conclusion, the introduction of mould injection plastic has brought about a manufacturing revolution, allowing for the production of complex, cost-effective, and visually appealing products across various sectors. With its numerous advantages, including design flexibility, production speed, and cost-effectiveness, this technique has become a game-changer. Companies like {}, with their expertise and commitment to excellence, continue to drive innovation and shape the future of manufacturing.

High-quality Injection Molding Services for ABS Plastic Parts

Title: Pioneering ABS Plastic Parts Injection Molding Services Revolutionize Manufacturing IndustryIntroduction:In a rapidly evolving world driven by technological advancements, companies are continually seeking innovative ways to enhance their manufacturing processes. One such company, which for confidentiality purposes we shall refer to as "ABC Manufacturing," has emerged as a pioneer in revolutionizing the production of ABS plastic parts through their groundbreaking injection molding services. With an unwavering commitment to quality, efficiency, and client satisfaction, ABC Manufacturing has become a leading name in the industry.I. Overview of ABS Plastic Parts Injection Molding Services:Injection molding is a widely acclaimed manufacturing technique that involves creating complex and durable plastic parts through the injection of molten material into a mold cavity. ABS plastic, known for its exceptional strength, impact resistance, and heat resistance, has become a sought-after material for a variety of applications, ranging from automotive components to electronics and consumer goods.ABC Manufacturing employs state-of-the-art injection molding machinery, operated by a highly skilled workforce, to produce ABS plastic parts of exceptional quality. Their commitment to incorporating cutting-edge technology allows for precision in design, resulting in products that meet the most stringent industry standards.II. Advantages of ABS Plastic Parts Injection Molding:1. Versatility: The injection molding process enables the creation of highly intricate and complex designs with precise detailing, meeting the diverse needs of industries such as automotive, electronics, and medical equipment.2. Cost-effective Production: With the ability to create large volumes of parts in a relatively short span, ABS plastic parts injection molding offers a cost-effective solution for mass production. This ensures the reduction of production costs and allows businesses to stay competitive in the market.3. Enhanced Durability: ABS plastic possesses excellent mechanical properties, including high strength and impact resistance. These characteristics make it an ideal choice for manufacturing parts that require durability and longevity.4. Aesthetically Appealing: Injection molding provides a smooth and uniform finish, making ABS plastic parts visually appealing. This allows businesses to enhance the branding and marketability of their products.III. ABC Manufacturing's Unique Approach:1. Extensive Experience: With several years of experience in the industry, ABC Manufacturing has amassed a wealth of knowledge and expertise in delivering customized ABS plastic parts. Their team of engineers collaborates closely with clients to understand their specific requirements, ensuring the production of parts that perfectly match their needs.2. Cutting-edge Technology: ABC Manufacturing constantly updates their production processes to incorporate the latest technological advancements. Through advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software, they ensure precision in part geometry and dimensional accuracy. This commitment to innovation enables them to produce high-quality products efficiently.3. Quality Assurance: ABC Manufacturing places a strong emphasis on quality control and assurance. They have implemented strict inspection protocols at every stage of the production process, guaranteeing consistently excellent results. Furthermore, their commitment to sustainability extends to the use of environmentally friendly ABS materials, ensuring an eco-conscious approach to manufacturing.IV. Market Impact and Future Prospects:ABC Manufacturing's ABS plastic parts injection molding services have made a significant impact on the manufacturing industry. Their innovative approach has enabled companies to enhance their production efficiency, reduce costs, and deliver top-notch products to the market. As demand for ABS plastic parts continues to grow, ABC Manufacturing is strongly positioned to maintain its leading role in the industry.Conclusion:ABC Manufacturing's ABS plastic parts injection molding services have reimagined the manufacturing landscape. Their commitment to excellence, unwavering dedication to technological innovation, and relentless pursuit of customer satisfaction have propelled them to the forefront of the industry. Through their groundbreaking production processes, they continue to redefine what is possible in the world of ABS plastic parts manufacturing.